полная версия

полная версияHandwork in Wood

Carriage-bolts are distinguished by having the part of the shank which is near the head, square.

Machine-bolts have square, hexagonal, or button heads.

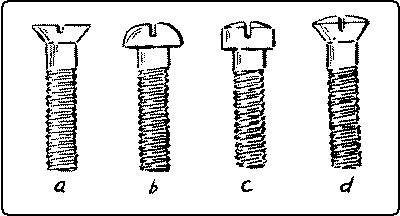

Machine-screws, Fig. 231, are similar to stove-bolts, but are accurately cut and are measured with a screw-gage. The varieties are, a, flat-head, b, round-head, c, fillister-head, d, oval-countersunk-head, all with slots for screwdriver.

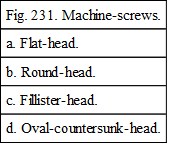

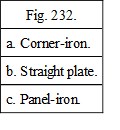

Plates, Fig. 232, include corner-irons, straight plates and panel-irons. These are made of either iron or brass and are used in fastening legs to the floor, in stiffening joints, affixing tops, etc.

Dowel-rods. Dowel-rods are cylindrical rods, from 3⁄16" to 1" in diameter, and 36", 42", and 48" long. They are commonly made of birch or maple, but maple is more satisfactory as it shrinks less and is stronger than birch.

Dowels are used as pins for joining boards edge to edge, and as a substitute for mortise-and-tenon joints.

There is, to be sure, a prejudice against dowels on the part of cabinet-makers due, possibly, to the willingness to have it appear that doweling is a device of inferior mechanics. But doweling is cheaper and quicker than tenoning, and there are many places in wood construction where it is just as satisfactory and, if properly done, just as strong. Certain parts of even the best furniture are so put together.

Shoe pegs serve well as small dowels. They are dipped in glue and driven into brad-awl holes.

Wedges are commonly used in door construction between the edges of tenons and the insides of mortises which are slightly beveled, No. 34, Fig. 266, p. 179. Or the end of a tenon may be split to receive the wedges, No. 35, Fig. 266. The blind wedge is used in the fox-tail joint, No. 36, Fig. 266.

GLUEGlue is an inferior kind of gelatin, and is of two kinds,—animal glue and fish glue. Animal glue is made of bones and trimmings, cuttings and fleshings from hides and skins of animals. Sinews, feet, tails, snouts, ears, and horn pith are also largely used. Cattle, calves, goats, pigs, horses, and rabbits, all yield characteristic glues.

The best glue is made from hides of oxen, which are soaked in lime water until fatty or partly decayed matter is eaten out and only the glue is left. The product is cleaned, boiled down and dried.

The best and clearest bone glues are obtained by leaching the bones with dilute acid which dissolves out the lime salts and leaves the gelatinous matters. Such leached bone is sold as a glue stock, under the name of "osseine." This material together with hides, sinews, etc., has the gelatin or glue extracted by boiling again and again, just as soup stock might be boiled several times. Each extraction is called a "run." Sometimes as many as ten or fifteen runs are taken from the same kettle of stock, and each may be finished alone or mixed with other runs from other stock, resulting in a great variety of commercial glues.

Manufacturers use many tests for glue, such as the viscosity or running test, the odor, the presence of grease or of foam, rate of set, the melting-point, keeping properties, jelly strength (tested between the finger tips), water absorption (some glues absorb only once their weight, others ten or twelve times), and binding or adhesive tests. This latter varies so much with different materials that what may be good glue for one material is poor for another.

Putting all these things together, glues are classified from grade 10 to 160, 10 being the poorest. The higher standards from 60 and upwards are neutral hide glues, clear, clean, free from odor, foam, and grease. The lower standards are chiefly bone glues, used for sizing straw hats, etc. They are rigid as compared with the flexibility of hide glues. For wood joints the grade should be 70 or over. For leather, nothing less than 100 should be used, and special cements are better still.

The best glue is transparent, hard in the cake, free from spots, of an amber color, and has little or no smell. A good practical test for glue is to soak it in water till it swells and becomes jelly-like. The more it swells without dissolving the better the quality. Poor glue dissolves. Glue is sometimes bleached, becoming brownish white in color, but it is somewhat weakened thereby.

Fish glue is made from the scales and muscular tissue of fish. Isinglass is a sort of glue made from the viscera and air bladder of certain fish, as cod and sturgeon.

Liquid glue may be made either from animal or fish glue. The LePage liquid glue is made in Gloucester, Mass., one of the greatest fish markets in the country. Liquid glue is very convenient because always ready, but is not so strong as hot glue, and has an offensive odor. Liquid glues are also made by rendering ordinary glue non-gelatinizing, which can be done by several means; as, for instance, by the addition of oxalic, nitric, or hydrochloric acid to the glue solution.

To prepare hot glue, break it into small pieces, soak it in enough cold water to cover it well, until it is soft, say twelve hours, and heat in a glue-pot or double boiler, Fig. 243, p. 149. The fresher the glue is, the better, as too many heatings weaken it. When used it should be thin enough to drip from the brush in a thin stream, so that it will fill the pores of the wood and so get a grip. Two surfaces to be glued together should be as close as possible, not separated by a mass of glue. It is essential that the glue be hot and the wood warm, so that the glue may remain as liquid as possible until the surfaces are forced together. Glue holds best on side grain. End grain can be made to stick only by sizing with thin glue to stop the pores. Pieces thus sized and dried can be glued in the ordinary way, but such joints are seldom good. Surfaces of hard wood that are to be glued should first be scratched with a scratch-plane, Fig. 111, p. 79.

To make waterproof glue, add one part of potassium bichromate to fifty parts of glue. It will harden when exposed to the air and light and be an insoluble liquid.13

General directions for gluing.14 Before applying glue to the parts to be fastened together, it is a good plan to assemble them temporarily without glue, to see that all the parts fit. When it is desirable that a certain part, as the panel, in panel construction, should not be glued in place, it is a wise precaution to apply wax, soap, or oil to its edges before insertion. Since hot glue sets quickly, it is necessary after the glue is applied to get the parts together as soon as possible. One must learn to work fast but to keep cool. To expedite matters, everything should be quite ready before the process is begun, clamps, protecting blocks of wood, paper to protect the blocks from sticking to the wood, braces to straighten angles, mallet, try-square, and all other appliances likely to be required.

Whenever it is possible to break up the process into steps, each step can be taken with more deliberation. For example, in assembling framed pieces that are doweled, it is well to glue the dowels into one set of holes beforehand, making tenons of them, as it were. Time is thus saved for the final assembling when haste is imperative. The superfluous glue around the dowels should be carefully wiped off.

Likewise in gluing up framed pieces, sections may be put together separately: as, the ends of a table, and when they are dry then the whole may be assembled. When the pieces are together the joints should be tested to see that they are true, and that there are no twists.

A good way to insure squareness, is to insert a diagonal brace on the inside, corner to corner, as in Fig. 294, p. 196. Such a brace should be provided when the trial assembly is made. Another good way to insure squareness is to pass a rope around two diagonally opposite posts, and then by twisting the rope, to draw these corners toward each other until the frame is square.

The superfluous glue may be wiped off at once with a warm damp cloth, but not with enough water to wet the wood. Or by waiting a few minutes until the glue thickens, much of it can readily be peeled off with an edge tool. Either of these ways makes the cleaning easier than to let the superfluous glue harden.

The work when glued should remain at least six hours in the clamps to harden.

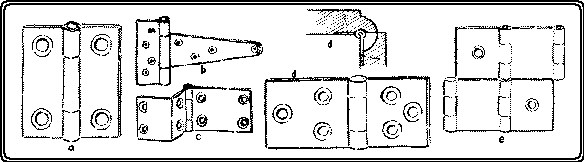

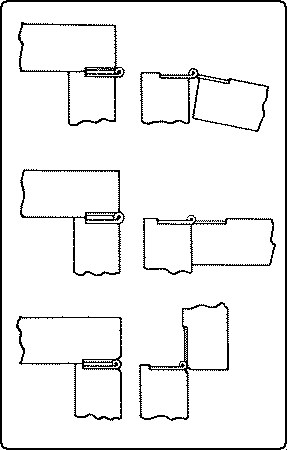

HINGESHinges, Fig. 233, are made in several forms. The most common are the butt-hinge or butt, the two leaves of which are rectangular, as in a door-hinge; the strap-hinge, the leaves of which are long and strap-shaped; the Tee-hinge, one leaf of which is a butt, and the other strap-shaped; the chest-hinge, one leaf of which is bent at a right angle, used for chest covers; the table-hinge used for folding table tops with a rule joint; the piano-hinge, as long as the joint; the blank hinge or screen-hinge which opens both ways; the stop-hinge, which opens only 90°; and the "hook-and-eye" or "gate" hinge.

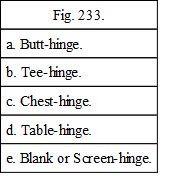

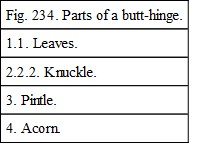

The knuckle of the hinge is the cylindrical part that connects the two leaves, Fig. 234. The "acorn" is the head of the "pintle" or pin that passes thru the knuckle. Sizes of butts are indicated in inches for length, and as "narrow," "middle," "broad" and "desk" for width. The pin may be either riveted into the knuckle as in box-hinges or removable as in door-butts. Sometimes, as in blind-hinges, the pintle is fastened into one knuckle, but turns freely in the other.

A butt-hinge may be set in one of three positions, Fig. 235: (1) Where it is desired to have the hinge open as wide as possible, as in a door. Here the knuckle is set well out from the wood. (2) Where it is desired to have the hinged portion open flat and no more. Here the center of the pin is in line with the outside surface of the wood. This is less likely to rack the hinge than the other two positions. (3) Where it is desired to have the knuckle project as little as possible.

Fig. 235. Three Positions of Hinges.

HINGING

In setting the hinges of a box cover, first see that the cover fits the box exactly all the way around.

In the case of a door, see that it fits its frame, evenly all the way around, but with a little play. To insure a tighter fit at the swinging edge this edge should be slightly beveled inwards.

In attaching a butt-hinge, the essential thing is to sink the hinge into the wood, exactly the thickness of the knuckle. The gains may be cut in one or both of the pieces to be hinged together.

With these matters determined proceed as follows: In the case of a box cover, the hinges should be set about as far from the ends of the box as the hinge is long.

In the case of an upright door, locate the hinges respectively above and below the lower and upper rails of the door. Mark with the knife on the edge of the door the length of the hinge, and square across approximately the width of the gain to receive it. Do this for both hinges. Between these lines gage the proper width of the gains. Set another gage to one half the thickness of the knuckle and gage on the door face the depth of the gains. Chisel out the gains, set the hinges in place, bore the holes, and drive the screws. Place the door in position again to test the fit. If all is well, mark the position of the hinges on the frame, gage and cut the gains, and fasten in the hinges. Where the hinge is gained its full thickness into the door, no gain, of course, is cut in the frame. If the hinges are set too shallow, it is an easy matter to unscrew one leaf of each and cut a little deeper. If they are set too deep the screws may be loosened and a piece of paper or a shaving inserted underneath along the outer arris of the gain.

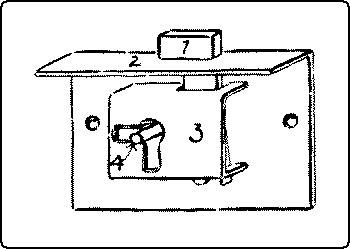

LOCKSThe chief parts of a lock are: the bolt, its essential feature, the selvage, the plate which appears at the edge of the door or drawer, the box, which contains the mechanism including the tumbler, ward, spring, etc., the key-pin, into or around which the key is inserted, the strike, the plate attached opposite the selvage, (often left out as in drawer-locks, but essential in hook-bolt locks, and self-locking locks,) and the escutcheon, the plate around the keyhole.

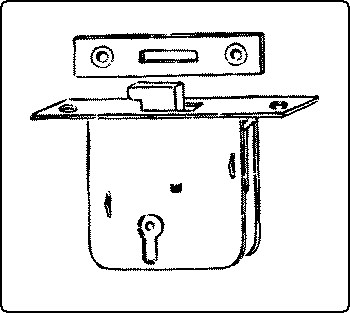

Locks may be classified: (1) According to their uses, of which there are two types. (a), Fig. 236, For drawers, cupboards, tills, wardrobes, and doors. In these the bolt simply projects at right angles to the selvage into the strike, and resists pressure sidewise of the lock. (b), Fig. 237, For desks, roll-top desks, chests, boxes and sliding doors. In these, the bolt includes a hook device of some kind to resist pressure perpendicular to the selvage. In some locks, the hook or hooks project sidewise from the bolt, in others the bolt engages in hooks or eyes attached to the strike.

Fig. 236. Rim-lock, for Drawer.

1. Bolt. 2. Selvage.

3. Box. 4. Key-pin.

Fig. 237. Mortise-lock, for Box.

(2) According to the method of application, as rim locks, which are fastened on the surface, and mortise locks which are mortised into the edge of a door or drawer or box.

INSERTING LOCKSTo insert a rim-lock, measure the distance from the selvage to the key-pin, locate this as the center of the keyhole, and bore the hole. If the lock has a selvage, gain out the edge of the door or drawer to receive it. If the lock box has to be gained in, do that next, taking care that the bolt has room to slide. Cut the keyhole to the proper shape with a keyhole-saw or small chisel. Fasten the lock in place, and if there is a strike or face-plate, mark its place and mortise it in.

To insert a mortise-lock, locate and bore the keyhole, mortise in the box and the selvage, finish the keyhole, fasten in the lock, add the escutcheon, locate and mortise in the strike, and screw it in place.

WOOD FASTENINGSReferences15:

Hammacher & Schlemmer.

Catalog No. 151.

Nails.

Goss, p. 153.

Purfield, Wood Craft, 5: 181.

Park, pp. 129-135.

Griffith, pp. 75-78.

Wood Craft, 5: 103.

Wheeler, pp. 428-433.

Tacks.

Wheeler, pp. 429-433.

Sickels, p. 70.

Goss, p. 155.

Barter, pp. 84-86.

Screws.

Goss, p. 155.

Wheeler, p. 476.

Barter, p. 86.

Griffith, pp. 78-80.

Park, pp. 136-140.

Dowels.

Goss, p. 153.

Wheeler, p. 374.

Sickels, p. 104.

Griffith, p. 92.

Wedges.

Goss, p. 151.

Glue.

Goss, p. 156.

Rivington, III, p. 432.

Barter, p. 82.

Standage, Wood Craft, 7: 48.

Park, pp. 141-146.

Sickels, p. 106.

Wheeler, pp. 391-396.

Alexander, Wood Craft, 5: 168.

Griffith, pp. 80-83.

Hinges.

Sickels, p. 118.

Wheeler, p. 402.

Chapter VI.

EQUIPMENT AND CARE OF THE SHOP

Tool equipment. The choice of tools in any particular shop best comes out of long experience. Some teachers prefer to emphasize certain processes or methods, others lay stress on different ones. The following tentative list is suggested for a full equipment for twenty-four students. One bench and its tools may be added for the teacher.

The prices given are quoted from Discount Sheet No. 1 for Catalogue of Tools, No. 355 issued by Hammacher, Schlemmer & Co., Fourth Avenue and 13th Street, New York City, dated 1908, and are correct at the present date (1910). Aggregate orders, however, are always subject to special concessions, and it is suggested that before ordering the purchaser submit a list of specifications for which special figures will be quoted.

There are good benches, vises, and tools of other makes on the market, but those specified below are typical good ones.

Following are two equipments for classes of twenty-four pupils, one severely economical to cost approximately $400, and the other more elaborate to cost approximately $750.

$400 TOOL EQUIPMENTINDIVIDUAL TOOLS

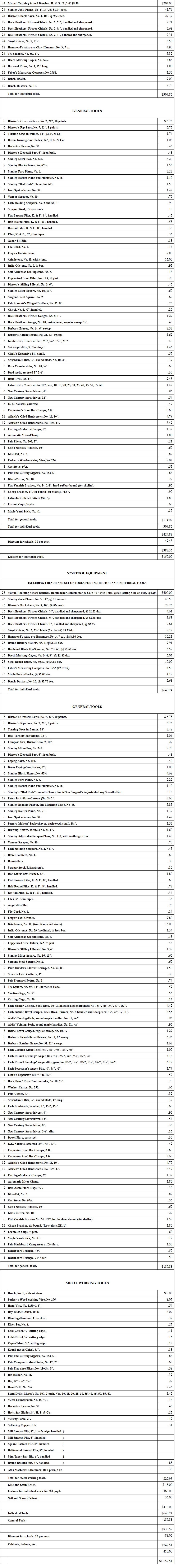

The general arrangement of the room. The important factors are the source or sources of light, and the lines of travel. The common arrangement of benches where two sides of the room are lighted, is shown in a, Fig. 238. By this arrangement, as each worker faces his bench, he also faces one set of windows and has another set of windows at his left. The advantage of this arrangement is that it is easy to test one's work with the try-square by lifting it up to the light. Another arrangement, shown in b, Fig. 238, has this advantage, that there are no shadows on the work when it is lying on the bench and the worker is holding his rule or try-square on it with his left hand. When all the windows are on one side of the room the latter is the more advantageous arrangement.

In determining the position of the benches, especially with reference to their distance from each other, thought should be given to the general lines of travel, from the individual benches to the general tool-rack, to the finishing-table, to the lockers, etc. Even if all the aisles cannot be wide enough both for passage and for work, one wider one thru the center of the room may solve the difficulty. Where rooms are crowded, space may be economized by placing the benches in pairs, back to back, c and d, Fig. 238. In any case, room should always be reserved for a tier of demonstration seats, facing the teacher's bench, for the sake of making it easy for the pupils to listen and to think.

Fig. 238. Four Different Arrangements of Benches in a Shop.

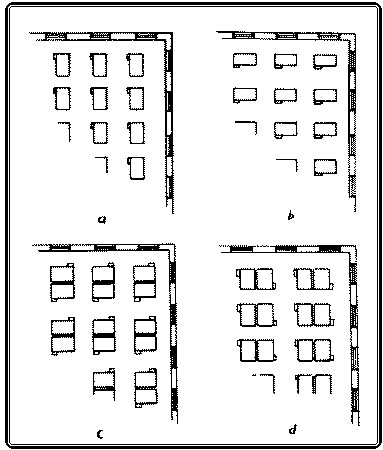

The Tools. Every shop soon has its own traditions as to the arrangement of tools, but there are two principles always worth observing. (1) It is an old saying that there should be "a place for everything and everything in its place." This is eminently true of a well-ordered woodworking shop, and there is another principle just as important. (2) Things of the same sort should be arranged together, and arranged by sizes, whether they be general tools or individual tools. In arranging the rack for general tools, a few suggestions are offered. In the first place, arrange them so that there will be no danger of cutting one's fingers on one tool when attempting to take down another. Where the rack must needs be high, all the tools can be brought within reach, by placing long tools, like files, screwdrivers, etc., at the top. Such an arrangement is shown in Fig. 239.

Fig. 239. General Tool rack in a School Shop.

As to the individual benches, those without high backs are to be preferred, not only because of their convenience when it is desired to work on large pieces, like table tops, and because the backs do not interfere with the light, but because it is easier for the teacher to look over the room to see that everything is in order. If the equipment is kept complete, it is an easy matter to glance over all the benches and the general rack to see that everything is in place.

In general, there are two methods of keeping guard over tools, the open and the closed. In the open method, everything is kept in sight so that empty places can be discovered readily. This method is a convenient one, and, besides, the tools are always easily accessible. In the closed method, the tools are kept in drawers and cases where they can be locked up. This method is suitable where pupils are equipped with individual sets of cutting tools. In such a case, the common tools for each bench are kept in a common drawer and individual pupils' tools in separate drawers. This method has the disadvantage that things are out of sight, and if they disappear their loss may not be discovered immediately. On the other hand, where the drawers and cases are kept carefully locked, the danger of loss is reduced almost to a minimum. Sometimes a combination of both methods is tried, the tools being kept in unlocked drawers. This method furnishes the greatest difficulty in keeping tools from disappearing.

Even when tools are well arranged, one of the most serious difficulties in the way of shop order, is to keep tools in their places. Pupils who are in a hurry, slip in the tools wherever they will fit, not where they belong. Labels at the places of the different sets may help somewhat; a more efficient method is to paste or paint the form of each tool on the wall or board against which it hangs. Pupils will see that, when they will not stop to read a label.

In spite of all precautions, some tools will disappear. A plan to cover the cost of these, which works well in some schools, is to require a deposit at the beginning of the year to cover these losses. Then at the end of the year, after deducting the cost of losses, the balance is returned pro rata.

There is diversity of practice in the distribution of tools on the general case and on the individual benches. Some tools, like the plane and chisel, and try-square, are so frequently in use that each worker must have one at hand. As to others, the demand must determine the supply. One other consideration may be expressed by the principle that those tools, the use of which is to be encouraged, should be kept as accessible as possible, and those whose use is to be discouraged, should be kept remote. Some tools, like files, it may be well to keep in a separate locker to be had only when asked for.

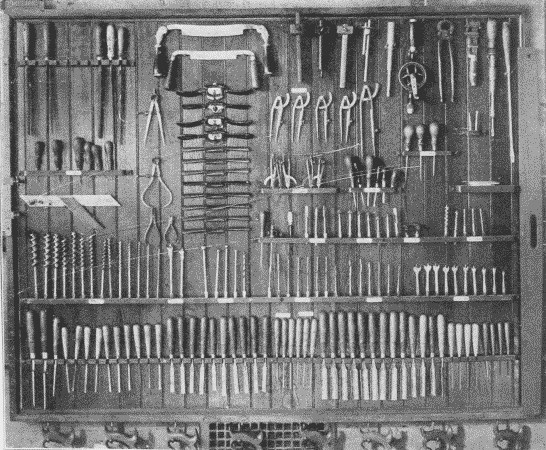

A cabinet of drawers, such as that shown in Fig. 240, for holding nails, screws, and other fastenings, is both a convenience and a material aid in preserving the order of the shop.

Fig. 240. Nail and Screw Cabinet.

As for the care of tools during vacation, they should be smeared with vaseline, which is cheap, and put away out of the dampness. The planes should be taken apart and each part smeared. To clean them again for use, then becomes an easy matter. The best method of removing rust and tarnish is to polish the tools on a power buffing wheel on which has been rubbed some tripoli. They may then be polished on a clean buffer without tripoli.

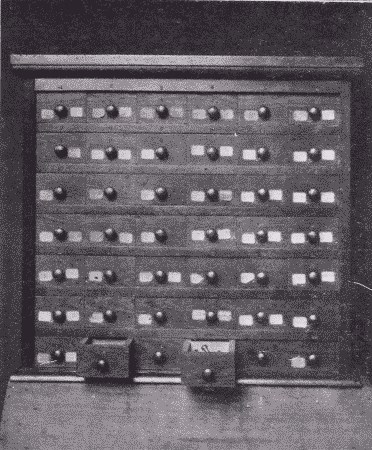

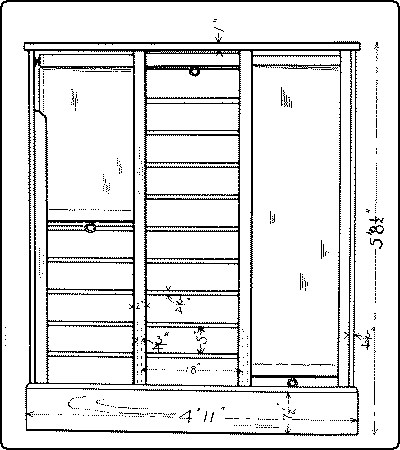

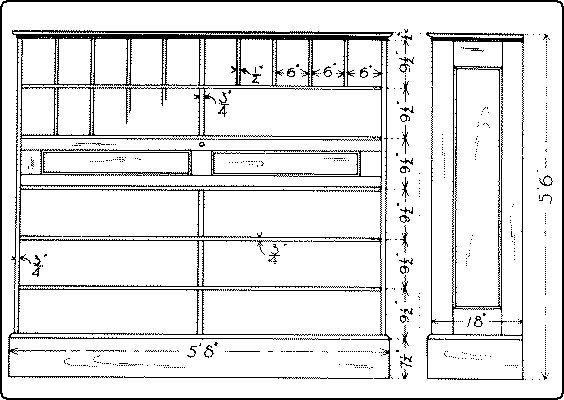

The Lockers. In order to maintain good order in the shop, an almost indispensable part of the equipment is a set of lockers for holding the unfinished work of pupils. An inexpensive outfit may consist simply of sets of shelves, say 5" apart, 12" deep, and 18" long, Fig. 241. Ordinary spring-roller curtains may be hung in front of each set of shelves to conceal and protect the contents. Such a case should cost at the rate of about 40c. for each compartment. A more substantial and more convenient case, shown in Fig. 242, consists of compartments each 9½" high, 6" wide, and 18" deep. These proportions may be changed to suit varying conditions. In front of each tier of 12 compartments is a flap door opening downward. Such a case built of yellow pine (paneled) may cost at the rate of $1.00 per compartment.

Fig. 241. An Inexpensive Locker for Unfinished Work.

Fig. 242. A More Expensive Locker for Unfinished Work.