Полная версия

Installation, starting and adjustment of ventilation and air conditioning systems A Guide

Alexey Antipov, Valery Korostylev, Mohamed Hello

Installation, starting and adjustment of ventilation and air conditioning systems A Guide

Chapter I. Motivation of a specialist in ventilation and its installations

Many people believe that the main motivation In any professional field is earning money and promotion at work. On the one hand, these are really the main Motives for people to work every day ( sometimes through force) why people go to work every day (not always the favourite one). However, we can find many people Who are unassuming and work for lower fee being completely satisfied with their job works for less salary because they are beloved with their job. So what motivates a ventilation engineer to work in this sphere?

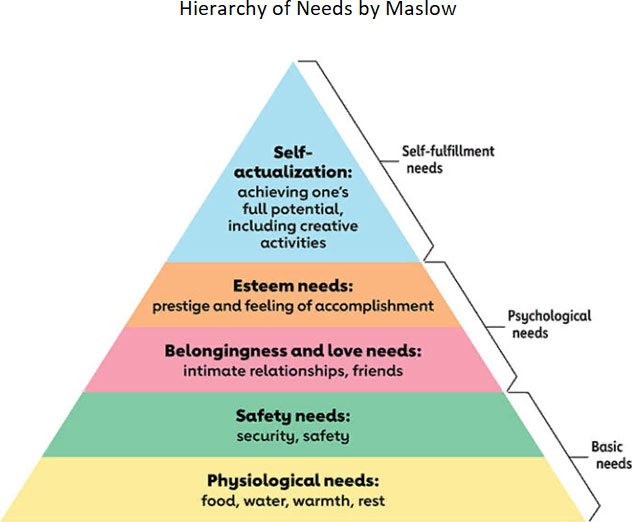

American psychologist Abraham Maslow has identified deep motives common to all people that determine human behavior.The psychologist believed that physical survival is the first deep motive and basic human need. After he is satisfied, the person will switch to the next need. As soon as it is completed, it is the turn of the next one, there are only five main motives:

1. Physiological needs

These include air, food, drink, shelter, clothing, warm, sleep – everything that is necessary for human survival. Maslow included sex in the same group. The psychologist considered these needs to be the most important – in a situation of extreme need, a person, first of all, will think about how to survive, that is, about physiological needs. Until they are satisfied, it is unlikely that he will have other desires.

2. Safety and security

As soon as the physiological needs of a person are satisfied, the desire for security and confidence in the future come to the fore. People want to control their lives, see order and predictability around them. In society, this means the absence of direct threats to life and health, protection from natural disasters, social stability, financial security, and so on. The police, rescue services, medical and municipal institutions in general close these needs of people in society.

3. Social needs

Initially, Maslow called them "the need for love." He believed that after satisfying physiological needs and obtaining security, a person expects love and affection from other people. This block of the pyramid includes social relations: family and relatives relationship, friendship, a sense of trust in others and acceptance of a person by others.

4. Respect and recognition

Maslow divided these needs into two types: self-esteem (self-esteem, personal achievements, independence from others) and to be respected by others. A person wants to feel important both in his own eyes and in the eyes of other people. Self-esteem is directly related to a sense of self-confidence and self-worth, with self-acceptance and self-worth. Respect from others is associated with the desire to be approved by others, successful and appreciated.

5. Self-actualization

Maslow considers, that self – actualization is the ability of a person to do what he was created for. A musician feels the need to make music, an artist – to draw, a poet – to write. If a person wants to be happy, he must do what he was born for. This desire to develop one's potential is the highest need in Maslow's hierarchy. At the same time, the psychologist notes that the specific behavior into which this need will develop varies from person to person. For one, this will be expressed in the desire to become an ideal parent, for another it will be associated with sporting achievements, for a third it will be a joy to create or invent.

Fig.1. A. Maslow's pyramid of needs

To begin with, let's consider how much money you can earn constructing doing ventilation. That means we start from first stage.

Prices are given for September 2023.

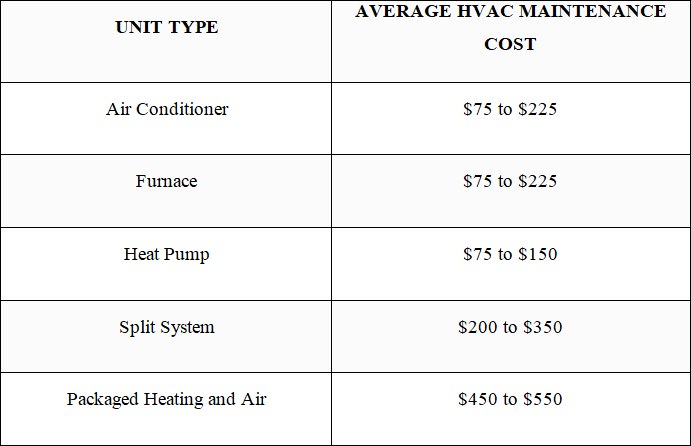

HVAC Maintenance Cost by Unit Type

HVAC repair costs will differ depending on the type of unit and how extensive the repair is. Here are some average service prices based on your HVAC unit:

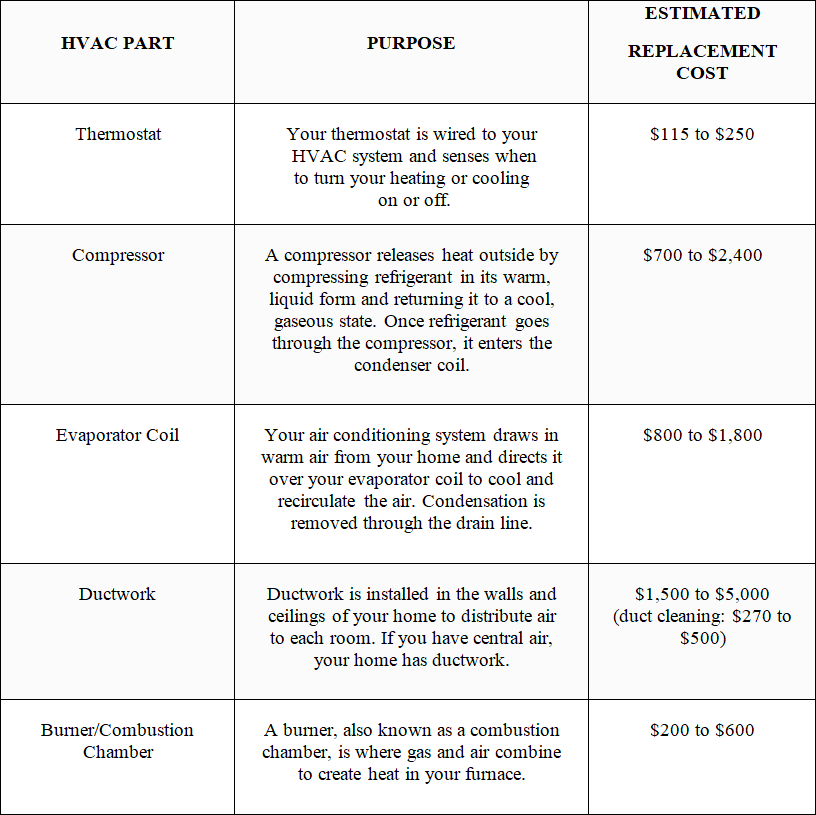

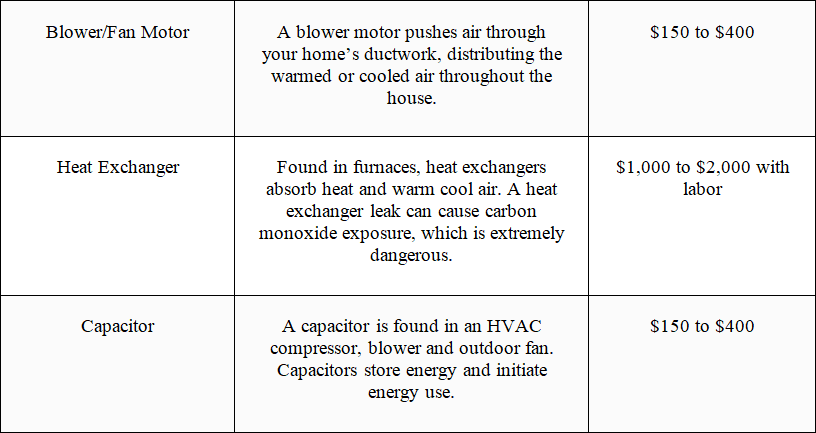

HVAC Service Cost by Part

If a component of your HVAC is starting to fail, you’ll need a replacement. HVAC companies will happily inspect your system and provide you with a quote for a part replacement. Here’s what you can expect:

From this table we can conclude that, any mater on Ventilation, can rise to the first step of the pyramid quite adequately. To master the remaining steps, we need to know the material outlined in the following chapters.

Questions to Chapter 1

1. Name the five steps in the hierarchical model of human needs according to the theory of Abraham Maslow.

2. Evaluate the implementation of this model on the example of work in the field of installation of ventilation systems.

3. Give an example of self-actualization in your current profession.

4. Count the advantages of the profession of an installer of ventilation systems over other professions basing on of the above model.

5. Give a comparative analysis of prices (for example, the installation of fans) from several sources on the Internet. Formulate the cost structure of the service as you see it.

Chapter II. Purpose and arrangement of ventilation systems

Purpose of ventilation systems

The state of the air is characterized by its main parameters: temperature, relative humidity, mobility (speed).

A person feels good only in a fairly narrow range of combinations of various air parameters.

The air parameters can be optimal, at which a person feels comfortable, and acceptable, at which a person's well-being and productivity of his work differs slightly from optimal. Thus, for industrial premises in the cold period of the year, the following optimal air parameters are set for medium-heavy work: temperature 18–20 °C, relative humidity 40–60% and mobility no more than 0.2 m/s.

The permissible air parameters for the same conditions have a wider range: temperature 17–23 °C, relative humidity no higher than 75% (the lower edge is not limited) and mobility no more than 0.3 m/s. In industrial premises, the maintenance of permissible air parameters is most often provided for.

Production processes may be accompanied by the release of harmful gases and vapors to humans into the air of the working area of the premises, the amount of which depends on the characteristics of the technological process, the degree of sealing of equipment, etc. The content of harmful gases and vapors in the air of the working area should not exceed the maximum permissible concentration (MPC). The maximum permissible concentration is the maximum possible amount of a harmful substance, mg/m3, per unit volume of air, which during the entire working experience does not cause diseases or abnormalities in the health of people working in these conditions, and does not affect subsequent generations. In addition, a large amount of heat, as well as moisture and dust can come from the process equipment. The person involved in the production process is a generator of heat, moisture and carbon dioxide. The heat output of one worker to the environment is 150–300 Watts or more. Every hour from 60 to 400 g of water vapor evaporates from the surface of the human body. Respiratory system produces from 20 to 40 liters of carbon dioxide.

These hazards in the form of excess heat, moisture, harmful gases and vapors enter the surrounding air and blendes in, while its temperature, moisture content, gas content, dustiness increase. This involves changes in the chemical composition and physical properties of the air.

In order to maintain normal air parameters in the premises that meet sanitary and hygienic and technological requirements, we implement ventilation, which creates an organized air exchange-removes polluted air and supplies treated (heated or cooled, humidified or drained) fresh and clean air instead.

Ventilation in most cases can provide only acceptable sanitary and hygienic conditions in the premises. The air parameters, strictly defined by temperature and relative humidity, including optimal ones, can be reached by using air conditioning systems.

Classification of ventilation systems

Ventilation systems are divided into supply systems that supply fresh air to the premises, exhaust systems that remove dirty air from the premises, and air or air-heat curtains that prevent the penetration of cold air through the entrance or doors of buildings during the cold season.

Both supply and exhaust ventilation systems can be general and local type. General exchange systems are designed to supply and remove air evenly throughout the serviced room, to create an air environment with approximately the same parameters throughout the entire volume of the working area. Local exhaust systems remove the air in the places of formation of hazards from technological equipment, preventing the hazards from spreading throughout the entire volume of the room, polluting the entire air of the workshop. Local supply systems supply fresh air near workplaces, create an air shower or oasis – a restricted area in the production room where the parameters of the air environment meet sanitary and hygienic requirements.

Local exhaust ventilation is much more effective than central or general exchange ventilation, since it removes air from the places of formation of hazards with a higher concentration of them, does not allow the hazards to spread freely throughout the room, but such ventilation is not always feasible.

According to the method of air movement, all ventilation systems are either natural or mechanical.

In natural ventilation systems, air movement occurs due to the difference in densities of internal (heated and lighter) and external (colder and heavier) air.

In mechanical ventilation systems, air is moved by a fan or other equipment (a smoke pump, a blower, an ejector, etc.) driven by an electric motor. Mechanical systems are used much more often than natural ones, since the area of action of mechanical systems is much larger, and the cross sections of air ducts are smaller than in natural ventilation systems of the same capacity, due to higher air velocity. So, in the air ducts of natural ventilation systems, the air velocity is 0.5–2 m/s, and in the air ducts of mechanical systems 4–20 m/s.

During the operation of ventilation of any kind in the room, the air is forced to be changed. The ratio of the amount of fresh air supplied to the room for 1 hour to the internal volume of the room is called the multiplicity of air exchange. In real conditions, the multiplicity of air exchange can vary from 0.5 to 20 or more.

In addition to the designed air exchange carried out by ventilation systems, air can enter the premises by infiltration through leaks of windows, walls, doors, gates, etc. due to gravitational (natural) pressure and due to wind pressure. In the same way, air can be removed from the room.

If there are no harmful emissions in the room, then the supply ventilation systems are carried out in such a way that they take part of the air from the outside, and part from the room. This secondary use of air from the room for supply systems is called recirculation. It allows you to reduce the temperature difference between the supply air and the indoor air during the cold season, increase the relative humidity of the air and, most importantly, save heat (in winter) or cold (in summer).

Installation of ventilation systems

Natural ventilation systems can be ductless if air passes only through open apertures in external fences, or are ducted when air moves through ducts.

The operation of natural ventilation largely depends on the action of the wind. The wind, running into the building, creates an overpressure zone on the windward side, and a negative pressure zone on the leeward side. Controlled natural air exchange in the workshops of industrial buildings is called aeration. Such buildings are equipped with lanterns with shutters (transoms) that can be opened manually or by special mechanisms. The same opening valves are provided with window openings in the outer walls. By opening them partially or completely, you can create the required air exchange. Aeration is calculated only for the effect of gravitational pressure, since wind pressure is episodic and, as a rule, increases air exchange. Aeration is usually provided in industrial buildings with significant heat emissions.

The advantage of aeration is that air exchange is created without the help of fans, without consuming electricity. However, aeration provides only general exchange ventilation and does not provide cleaning of supply and exhaust air.

Mechanical ventilation systems can provide local ventilation.

The supply systems of mechanical ventilation supply purified air with a set temperature and, in some cases, humidity to the working area of the workshop to ensure the required sanitary and hygienic conditions for people and equipment inside the building. Mechanical ventilation exhaust systems remove dusty and polluted air, purifying it if necessary before being released into the atmosphere.

Supply ventilation systems consist of the following main elements: an air intake device, an intake chamber, which includes an insulated valve, a filter, an air heater (heater) and the fan, the network air ducts and air distributors, as well as regulating devices (diaphragms).

The air intake device is located in the least dusty area of the site, but as close as possible to the supply chamber or on the roof. At the entrance to the air intake shaft or channel, a louvered grille is installed to protect against atmospheric precipitation and from foreign objects. An air intake shaft or channel is made in building structures made of brick or concrete. Sometimes one intake duct feeds several supply systems with external air.

An insulated valve (flap) with manual or electric drive is installed between the air intake device and the filter of the supply chamber. When the fan is not working, the valve must be closed to protect the supply chamber equipment from outside cold air.

The supply chamber consists of a louvered grate, a filter for air purification, heaters for heating it and a fan with an electric motor. Supply chambers can be installed on a foundation or a platform, or suspended from ceiling structures of coatings. No fencing is required for these cameras.

Air ducts of supply systems are usually made of thin – sheet galvanized steel roofing with a thickness of 0.35–1.4 mm. The air ducts can be of round or rectangular cross-section. Metal ducts are quickly mounted, are strong enough and have good tightness. When laying air ducts under the floor, they are made of concrete or brick.

Air distributors (supply nozzles) are designed to distribute supply air. The supply air can be supplied to the working area; for this, the air distributors must have a short torch and a slight velocity of the outgoing air to eliminate the feeling of a draft. When air is supplied to the upper area of the room, on the contrary, the air outlet speed should be higher so that the fresh air stream reaches the working area.

Air distributors are installed in suspended ceilings, some are mounted at a low height above the working area.

A type of supply ventilation systems is air shower, which provides a concentrated flow of air to the workplace. A workplace is a platform with a diameter of 1 m, on which the worker is at least 4 hours per shift or 2 hours continuously. Such an air supply is necessary for intensive thermal (from 300 to 3000 W/m2 or more) irradiation of workers, or for open production processes with the release of harmful gases and vapors, when it is impossible to arrange local shelters. Actually, the scheme of air douching does not differ from the supply ventilation system, but instead of air distributors, showering rotary nozzles are installed.

Air and thermal-air curtains are designed to protect the gates and open entrances of industrial buildings from the intake of cold air in winter. There are two types of curtains: sliding, in which a flat jet of air is supplied either from below or from the sides of entrances and gates at some angle towards cold air, and mixing, when air from the building is supplied to the vestibule between the double entrance doors. Mixing curtains are used in administrative and public buildings, in passageways, etc. Curtains in which the air is preheated in an air heater are called thermal-air, and curtains that supply air without heating are simply air type.

Air-heating units with full or partial air recirculation are often used in air heating systems.

General exchange exhaust ventilation systems usually remove air from the upper, less often from the middle zone of buildings. Before removal, the air in general exchange exhaust systems usually does not undergo cleaning. General exchange exhaust systems can be channelless if the air is removed by roof fans that are installed on the floors, and ducted. In ducted exhaust ventilation systems, air is sucked into air intake apertures or grilles, it is fed through the ducts to the fan and, after passing the exhaust shaft, enters the atmosphere. To protect the exhaust shaft from atmospheric precipitation, an umbrella is installed above it, and the air ducts are blocked with a flap when the fan is not working.

Local exhaust ventilation systems are designed to take harmful emissions from the places of their formation with the help of shelters or local suction, transport polluted air, clean it in filters or dust collectors and release it into the atmosphere. Local suction and shelters have the most diverse design and shape: these are umbrellas, fume hoods, full shelters, side and ring suction at baths and shaft furnaces, suction panels, casings, etc.

Many harmful substances released during technological processes actively affect local suction pipes, air ducts, fans, filters, causing their severe corrosion, in addition, they can be explosive and fire-hazardous. In these cases, air ducts and other devices in contact with an aggressive environment are made of materials that are not subject to intense corrosion by the moving medium (corrosion-resistant alloy steels, aluminum, titanium. metal, vinyl, polyethylene, etc.), or apply special coatings of steel ducts with acid- and alkali-resistant dyes, enamels and varnishes. In such systems, fans and other equipment are installed in an intrinsically safe protected design.

Questions for chapter 2

1. Name the main parameters of the air environment.

2. What is the main purpose of the ventilation system?

3. In which cases the use of natural ventilation systems is justified.

4. What is the advantage of mechanical ventilation systems?

5. What is the name of the process of heat recovery of the removed air, what are its technical and economic advantages?

6. What material is used to produce ventilation ducts most often?

7. What, in your opinion, is affected by the thickness of the metal in the production of air ducts?

8. In which cases air showering is used?

9. Name the main processes of air treatment in the supply ventilation system.

10. In which cases a special design of air ducts and ventilation equipment is used?

Chapter III. Equipment of air ventilation systems

As indicated above, the required state of the air environment in the premises is maintained by general exchange ventilation methods by pumping clean ventilation air into the premises with the necessary temperature-humidity parameters and removal of air that does not meet regulatory requirements. In accordance with this, general exchange ventilation systems should include equipment and devices for intake of outdoor air, its processing, transportation and distribution around the premises, as well as for the removal of exhaust air.

3.1. Air intake and air discharge devices

These include air intake and air discharge devices in mechanical ventilation systems, which are made in the form of holes in the fences of buildings, attached or freestanding shafts. When air is taken from above, the air intake devices are placed in the attic or upper floor of the building, and the channels are removed above the roof in the form of shafts.

For aeration, air intake and ejection devices are made in the form of rotating transoms, opening lanterns, windows or other overlapping apertures in the fences of buildings.

The location and design of the air intake devices are selected taking into account the cleanliness of the intake air and the satisfaction of architectural requirements. Thus, air intake devices should not be located near sources of air pollution (emissions of polluted air or gases, chimneys, kitchens, unpaved roads, etc.).

Air intake apertures should be located at a height of at least 2 m from the ground surface and closed with louvered grilles (in the green zone – at a height of at least 1 m).

To protect the premises from outside cold air during standby of the ventilation through ventilation ducts, air intake and air discharge devices are equipped with multi-leaf insulated valves with manual or mechanical drive. In the latter case, the valve is blocked along with the fan closing the apertures. At low temperature of the outside air, the valves are supplied with an electric heating system in order to protect their flaps from freezing. Electric heating is turned on for 10–15 minutes before starting the fan (Fig.2).

Fig.2. Electric air valve

The outer walls of exhaust ducts and shafts are insulated to avoid condensation and ice of water vapor from the extracted moist air. The air velocity in the supply channels and shafts is supported between 2 and 5 m/s, in the channels and shafts of exhaust devices: 4–8 m/s, but not less than 0.5 m/s, including for natural ventilation.

3.2. Ventilation chambers

The main ventilation equipment of supply and exhaust installations, as a rule, is installed in special rooms called ventilation chambers. Supply chambers in public, administrative, residential buildings are usually designed on the ground floor or in the technical underground. Exhaust chambers should be located in the upper part of the building. In multi-storey buildings with a large number of ventilation systems, ventilation chambers are arranged in technical floors.

In buildings with a large number of ventilation systems (more than 5), a room for equipment repair is provided. The operation of ventilation systems is controlled from special remote controls using automation and remote control devices.

3.3. Fans

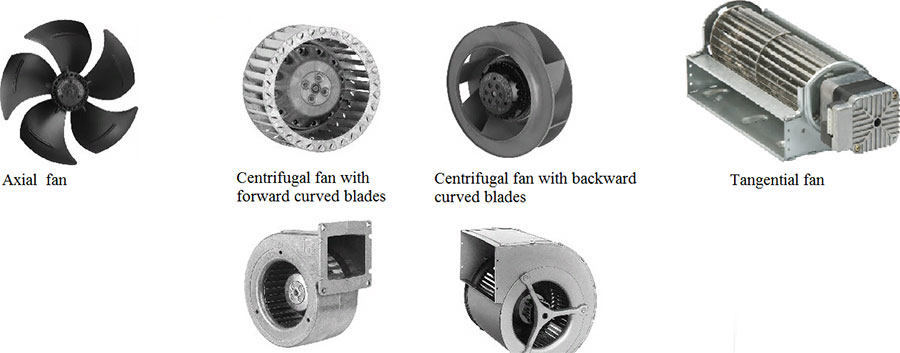

The fan is a mechanical device designed to move air through the ducts of ventilation systems, as well as to carry out direct air supply to the room or suction from the room, and creating the pressure drop necessary for this (at the inlet and outlet fan). According to the design and principle of operation, fans are divided into:), radial (centrifugal), diametral (tangential) (Fig.3).

Fig.3.Fan designs

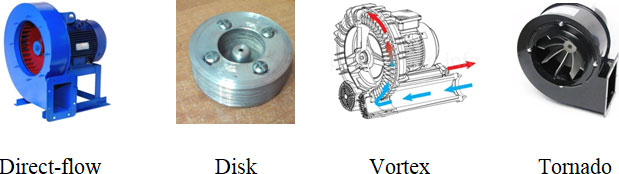

Currently, modifications of radial fans are used – direct-flow, disk, vortex, tornado (Fig.4).

Fig.4. Modifications of radial fans

Fans are evaluated by specific speed, which relates the rotational speed and pressure.