Полная версия

Exactly

The shells that endured this beating—and they would be randomly distributed, for once the ship had docked and the stevedores had unloaded the crates and the ammunition had been broken down and sent out to the various regiments, no one knew what order the shells would be in—would, as a result, not fit into the gun barrels out on the battlefield. There would, in consequence, be (and entirely randomly) a spate of misfires of the guns.

It was an elegant diagnosis, with a simple recommended cure: it was necessary only for the factory back in Detroit to reinforce the cardboard and wood of the ammunition crates and—presto!—the shell casings would all emerge from the ship unbruised and undistorted, and the jamming problem with the antitank rifles would be solved.

Povey telegraphed his news and his suggestion back to London, was immediately declared a hero, and then, in classic army style, was equally immediately forgotten about, in the desert, without orders, but with, as he had been away from his office in Washington for so long, a considerable amount of back pay.

Hot work in the Sahara it must have been, for at this point the story wavers a little: Mr. Povey Sr. seems to have gone on some kind of long-drawn-out desert bender. But after enjoying the sunshine for an indecent number of weeks, he decided that he did in fact need to return to America, so he bribed his way back there with bottles of Scotch whisky. It took him eleven bottles of Johnnie Walker to get from Cairo (via a temporary aerodrome in no less exotic a wartime stopover than Timbuktu) to Miami, after which it was but a short and easy hop up to Washington.

There he found dismaying news. It turned out that he had been away in Africa for so long without any communication that he had been declared missing and presumed dead. His mess privileges had been revoked, his cupboard closed, and all his clothes altered to fit a much smaller man.

It took a while for this discomfiting mess to be sorted out, and when eventually everything was more or less back to normal, he discovered that his entire ordnance unit had been transferred to Philadelphia—to which he promptly went as well.

There he met and fell in love with the unit’s American secretary. The pair got married, and Mr. Povey, never apparently practicing the Hinduism that had been engraved on his army dog tag, remained blamelessly in the United States for the rest of his days.

And, as my correspondent then wrote, with a flourish, “the lady in question was my mother, and so I exist—and I exist entirely because of precision.” This is why, he then added, “you must write this book.”

BEFORE WE DELVE too deeply into its history, two particular aspects of precision need to be addressed. First, its ubiquity in the contemporary conversation—the fact that precision is an integral, unchallenged, and seemingly essential component of our modern social, mercantile, scientific, mechanical, and intellectual landscapes. It pervades our lives entirely, comprehensively, wholly. Yet, the second thing to note—and it is a simple irony—is that most of us whose lives are peppered and larded and salted and perfumed with precision are not, when we come to think about it, entirely sure what precision is, what it means, or how it differs from similar-sounding concepts—accuracy most obviously, or its lexical kissing cousins of perfection and exactitude and of being just right, exactly!

Precision’s omnipresence is the simplest to illustrate.

A cursory look around makes the point. Consider, for example, the magazines on your coffee table, in particular the advertising pages. In a scant few minutes you could, for instance, construct from them a rough timetable for enjoying a precision-filled day.

You would begin your morning by first using a Colgate Precision Toothbrush; if you were clever enough to keep up with Gillette’s many product lines, you could enjoy less “tug and pull” on your cheek and chin by shaving with the “five precision blades” in its new Fusion5 ProShield Chill cartridge, and then tidying up your goatee and mustache with a Braun Precision Trimmer. Before the first meeting with a new acquaintance, be sure to have any former-girlfriend-related body art painlessly removed from your biceps with an advertised machine that offers patented “precision laser tattoo removal.” Once thus purified and presentable, serenade your new girlfriend by playing her a tune on a Fender Precision bass guitar; maybe take her for a safe wintertime spin after fitting your car with a new set of guaranteed-in-writing Firestone Precision radial snow tires; impress her with your driving skills first out on the highway and then at the curb with adroit use of the patented Volkswagen Precision parking-assist technology; take her upstairs and listen to soft music played on a Scott Precision radio (a device that will add “laurels of magnificent dignity to those of the world-record achievements” of the Chicago-based Scott Transformer Company—not all the magazines on an average coffee table are necessarily current). Then, if the snow has eased, prepare dinner in the back garden with a Big Green Egg outdoor stove equipped with “precision temperature control”; gaze dreamily over nearby fields newly sown with Johnson Precision corn; and finally, take comfort from the knowledge that if, after the stresses of the evening, you awake hungover or unwell, you can take advantage of the precision medicine that is newly available at NewYork-Presbyterian Hospital.

It took no time at all to tease out these particular examples from one randomly selected coffee-table pile. There are all too many others. I see, for instance, that the English novelist Hilary Mantel recently described the future British queen, née Kate Middleton, as being so outwardly perfect as to appear “precision-made, machine-made.” This went down well with neither royalists nor engineers, as what is perfect about the Duchess of Cambridge, and indeed with any human being, is the very imprecision that is necessarily endowed by genes and upbringing.

Precision appears in pejorative form, as here. It is also enshrined elsewhere and everywhere in the names of products, is listed among the main qualities of the function or the form of these products, is all too often one of the names of companies that produce such products. It is also used to describe how one uses the language; how one marshals one’s thoughts; how one dresses, writes by hand, ties ties, makes clothing, creates cocktails; how one carves, slices, and dices food—a sushi master is revered for the precise manner in which he shaves his toro—how cleverly one throws a football, applies makeup, drops bombs, solves puzzles, fires guns, paints portraits, types, wins arguments, and advances propositions.

QED, one might say. Precisely.

Precision is a much better word, a more apposite choice in all the examples just given, than is its closest rival, accuracy. “Accurate Laser Tattoo Removal” sounds not nearly as convincing or effective; a car with merely “Accurate Parking Technology” might well be assumed to bump occasional fenders with another; “Accurate Corn” sounds, at best, a little dull. And it surely would be both damning and condescending to say that you tie your tie accurately—to knot it precisely is much more suggestive of élan and style.

THE WORD precision, an attractive and mildly seductive noun (made so largely by the sibilance at the beginning of its third syllable), is Latin in origin, was French in early wide usage, and was first introduced into the English lexicon early in the sixteenth century. Its initial sense, that of “an act of separation or cutting off”—think of another word for the act of trimming, précis—is seldom used today:* the sense employed so often these days that it has become a near cliché has to do, as the Oxford English Dictionary has it, “with exactness and accuracy.”

In the following account, the words precision and accuracy will be employed almost but not quite interchangeably, as by common consent they mean just about the same thing, but not exactly the same thing—not precisely.

Given the particular subject of this book, it is important that the distinction be explained, because to the true practitioners of precision in engineering, the difference between the two words is an important one, a reminder of how it is that the English language has virtually no synonyms, that all English words are specific, fit for purpose by their often very narrow sense and meaning. Precision and accuracy have, to some users, a significant variation in sense.

The Latin derivation of the two words is suggestive of this fundamental variance. Accuracy’s etymology has much to do with Latin words that mean “care and attention”; precision, for its part, originates from a cascade of ancient meanings involving separation. “Care and attention” can seem at first to have something, but only something rather little, to do with the act of slicing off. Precision, though, enjoys a rather closer association with later meanings of minuteness and detail. If you describe something with great accuracy, you describe it as closely as you possibly can to what it is, to its true value. If you describe something with great precision, you do so in the greatest possible detail, even though that detail may not necessarily be the true value of the thing being described.

You can describe the constant ratio between the diameter and the circumference of a circle, pi, with a very great degree of precision, as, say, 3.14159265 358979323846. Or pi can happily be expressed with accuracy to just seven decimal places as 3.1415927—this being strictly accurate because the last number, 7, is the mathematically acceptable way to round up a number whose true value ends (as I have just written, and noted before the gap I have placed in it) in 65.

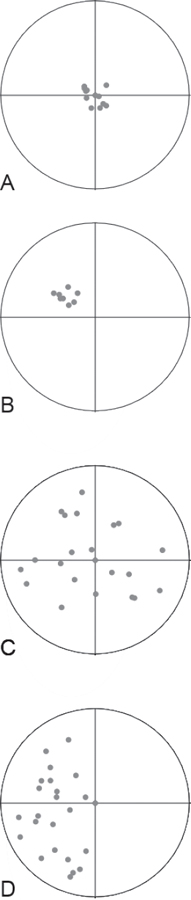

A somewhat simpler means of explaining much the same thing is with a three-ring target for pistol shooting. Let us say you shoot six shots at the target, and all six shots hit wide of the mark, don’t even graze the target—you are shooting here with neither accuracy nor precision.

Maybe your shots are all within the inner ring but are widely dispersed around the target. Here you have great accuracy, being close to the bull’s-eye, but little precision, in that your shots all fall in different places on the target.

Perhaps your shots all fall between the inner and outer rings and are all very close to one another. Here you have great precision but not sufficient accuracy.

The image of a target offers an easy means of differentiating precision and accuracy. In A, the shots are close and clustered around the bull: there is both precision and accuracy. In B, there is precision, yes, but insofar as the shots miss the bull, they are inaccurate. C, with the shots widely dispersed, shows neither precision nor accuracy. And in D, with some clustering and some proximity to the bull, there is moderate accuracy and moderate precision—but very moderate.

Finally, the most desired case, the drumroll result: your shots are all clustered together and have all hit the bull’s-eye. Here you have performed ideally in that you have achieved both great accuracy and great precision.

In each of these cases, whether writing the value of pi or shooting at a target, you achieve accuracy when the accumulation of results is close to the desired value, which in these examples is either the true value of the constant or the center of the target. Precision, by contrast, is attained when the accumulated results are similar to one another, when the shooting attempt is achieved many times with exactly the same outcome—even though that outcome may not necessarily reflect the true value of the desired end. In summary, accuracy is true to the intention; precision is true to itself.

One last definition needs to be added to this mass of confusion: the concept of tolerance. Tolerance is an especially important concept here for reasons both philosophical and organizational, the latter because it forms the simple organizing principle of this book. Because an ever-increasing desire for ever-higher precision seems to be a leitmotif of modern society, I have arranged the chapters that follow in descending order of tolerance, with large tolerances of 0.1 and 0.01 starting the story and the absurdly, near-impossibly tiny tolerances to which some scientists work today—claims of measurements of differences of as little as 0.000 000 000 000 000 000 000 000 000 01 grams, 10 to the -28th grams, have recently been made, for example—toward the end.*

Yet this principle also prompts a more general philosophical question: why? Why the need for such tolerances? Does a race for the ever-increasing precision suggested by these measurements actually offer any real benefit to human society? Is there perhaps a risk that we are somehow fetishizing precision, making things to ever-more-extraordinary tolerances simply because we can, or because we believe we should be able to? These are questions for later, but they nonetheless prompt a need here to define tolerance, so that we know as much about this singular aspect of precision as about precision itself.

Although I have mentioned that one may be precise in the way one uses language, or accurate in the painting of a picture, most of this book will examine these properties as far as they apply to manufactured objects, and in most cases to objects that are manufactured by the machining of hard substances: metal, glass, ceramics, and so forth. Not wood, though. For while it can be tempting to look at an exquisite piece of wooden furniture or temple architecture and to admire the accuracy of the planing and the precision of the joints, the concepts of precision and accuracy can never be strictly applied to objects made of wood—because wood is flexible; it swells and contracts in unpredictable ways; it can never be truly of a fixed dimension because by its very nature it is a substance still fixed in the natural world. Whether planed or jointed, lapped or milled, or varnished to a brilliant luster, it is fundamentally inherently imprecise.

A piece of highly machined metal, however, or a lens of polished glass, an edge of fired ceramic—these can be made with true and lasting precision, and if the manufacturing process is impeccable, they can be made time and time again, each one the same, each one potentially interchangeable for any other.

Any piece of manufactured metal (or glass or ceramic) must have chemical and physical properties: it must have mass, density, a coefficient of expansion, a degree of hardness, specific heat, and so on. It must also have dimensions: length, height, and width. It must possess geometric characteristics: it must have measurable degrees of straightness, of flatness, of circularity, cylindricity, perpendicularity, symmetry, parallelism, and position—among a mesmerizing host of other qualities even more arcane and obscure.

And for all these dimensions and geometries, the piece of machined metal must have a degree of what has come to be known* as tolerance. It has to have a tolerance of some degree if it is to fit in some way in a machine, whether that machine is a clock, a ballpoint pen, a jet engine, a telescope, or a guidance system for a torpedo. There is precious little point in tolerance if the machined object is simply to stand upright and alone in the middle of a desert. But to fit with another equally finely machined piece of metal, the piece in question must have an agreed or stated amount of permissible variation in its dimensions or geometry that will allow it to fit. That allowable variation is the tolerance, and the more precise the manufactured piece, the greater the tolerance that will be needed and specified.

A shoe, for instance, is invariably a thing of very low tolerance: on the one hand, a poorly made slipper may have “an agreed or stated amount of allowable variation in its dimensions” (which is the engineer’s formal definition of tolerance) of half an inch, with so generous an amount of wiggle room between foot and lining as to make the notion of precision almost irrelevant. A handmade brogue shoe by Lobb of London, on the other hand (or foot), may seem to fit snugly, perfectly, precisely even, but it will still have a tolerance of maybe an eighth of an inch—and in a shoe, such a tolerance would be acceptable, and the shoe indeed worn with pride. Yet, in terms of precision engineering, it is anything but precisely made; nor is it even accurately so.*

ONE OF THE two most precise measuring instruments ever built by human agency stands in America’s Pacific Northwest, far away from everything, in the arid middle of Washington State. It was built just outside the top-secret nuclear installation where the United States created the first supplies of plutonium for the bomb that destroyed Nagasaki, for decades the material at the heart of much of the nation’s arsenal of atomic weapons.

The years of nuclear activity there have left an unimaginably large legacy of dangerously irradiated substances, from old fuel rods to contaminated items of clothing, which are only now, and after a loud public outcry, being remedied—or remediated, the term environmentalists prefer. Today, the Hanford site, as it is known, is officially the largest environmental cleanup site in the world, with decontamination bills reaching the tens of billions of dollars and the necessary remedial work likely to last until the middle of the twenty-first century.

I first passed by the site very late one night, after a long drive from Seattle. From my southbound speeding car, I could see the glimmer of lights in the far distance. Behind razor-wire security fences and warning signs and under the protection of armed guards, some eleven thousand workers are now laboring night and day to cleanse the earth and waters of the poisonous radioactivity that so dangerously suffuses it. Some suppose it is a task so vast that it may never be properly completed.

To the south of the main cleanup site, just outside the razor-wire fence but within sight of the still-standing towers of the remaining atomic piles, one of present-day science’s most remarkable experiments is being conducted. It is not secret at all, is unlikely to leave a legacy of any danger whatsoever, and requires the making and employment of an array of the most precise machines and instruments that humankind has ever attempted to construct.

It is an unassuming place, easily missed. I arrived for my appointment in morning daylight, weary after the long nighttime drive. It was cold; the road was quite empty, the main turnoff unmarked. A small notice on the left pointed to a cluster of low white buildings a hundred yards off the road. “LIGO,” the sign read. “WELCOME.” And that was about all. Welcome to the current cathedral, it might also have said, to the worship of ultraprecision.

It has taken decades to design the scientific instruments that are secreted out in the middle of this dust-dry nowhere. “We maintain our security by our obscurity” is the motto for those who fret about the costly experiments sited there, all without a fragment of barbed wire or chain link to protect them. The tolerances of the machines at the LIGO site are almost unimaginably tiny, and the consequent precision of its components is of a level and nature neither known nor achieved anywhere else on Earth.

LIGO is an observatory, the Laser Interferometer Gravitational-Wave Observatory. The purpose of this extraordinarily sensitive, complex, and costly piece of equipment is to try to detect the passage through the fabric of space-time of those brief disruptions and distortions and ripples known as gravitational waves, phenomena that in 1916 Albert Einstein predicted, as part of his general theory of relativity, should occur.

If Einstein was right, then once every so often, when huge events occur far out in deep space (the collision of a pair of black holes, for instance), the spreading fan of interstellar ripples, all moving at the speed of light, should eventually hit and pass through the Earth and, in doing so, cause the entire planet to change shape, by an infinitesimal amount and for just the briefest moment of time.

No sentient being would ever feel such a thing; and the slight squeezing would be so minute and momentary and harmless that not a trace could ever be recorded by any machine or device known—except, in theory, by LIGO. And after decades of experiments with instruments that were being ever more refined to greater and greater degrees of sensitivity, the devices now running in the high northwest desert of Washington State and down in the bayous of Louisiana, where the second such observatory has been built, have indeed brought home the bacon.

For, in September 2015, almost a century after Einstein’s theory was first published, and then again on Christmas Eve that same year and then again in 2016, LIGO’s instruments showed without doubt that a series of gravitational waves, arriving after billions of years of travel from the universe’s outer edges, had passed by and through Earth and, for the fleeting moment of their passage, changed our planet’s shape.

TO DETECT THIS, the LIGO machines had to be constructed to standards of mechanical perfection that only a few years before were well-nigh inconceivable and that, before then, were neither imaginable nor even achievable. For it was not always so, this delicacy, this sensitivity, this ultraprecise manner of doing things. Precision was not always there, waiting in the shadows, needing to be found and then exploited for what its early admirers believed would be the common good. Far from it.

Precision was a concept that was invented, quite deliberately, out of a single and well-recognized historic need. It was brought into being for severely practical reasons—reasons that had much to do not with any dreamy twenty-first-century wish to confirm (or otherwise) the existence of vibrations from the collisions of distant stars. Rather, it had to do with a down-to-earth eighteenth-century realization of what was then a pressing matter of physics, and which was related to the potentially awesome power of that high-temperature form of water that since the century before had been known as and defined by the word steam.

Precision’s birth derives from the then-imagined possibility of maybe holding and managing and directing this steam, this invisible gaseous form of boiling water, so as to create power from it, and to demand that by the employment of this power, it perform useful work for the good (perhaps, and with luck) of all humankind.

And all that, what turned out to be one of the most singular of engineering epiphanies, took place in North Wales on a cool May day in 1776—by coincidence, within weeks of the founding of the United States of America, which would eventually make such use of the precision techniques that duly evolved.

That spring day is now generally (though not unanimously) agreed to mark the birth date for the making of the first construction possessed of a degree of real and reproducible mechanical precision—precision that was measurable, recordable, repeatable, and, in this case, created to the tolerance of one-tenth of an inch, or, as it was put at the time, of an English silver coin with a value or worth of just one shilling.

Chapter 1

(TOLERANCE: 0.1)

Stars, Seconds, Cylinders, and Steam

It is the mark of an instructed mind to rest assured with that degree of precision that the nature of the subject admits, and not to seek exactness when only an approximation of the truth is possible.

—ARISTOTLE (384–322 BC), NICOMACHEAN ETHICS

The man who by the common consent of the engineering fraternity is regarded as the father of true precision was an eighteenth-century Englishman named John Wilkinson, who was denounced sardonically as lovably mad, and especially so because of his passion for and obsession with metallic iron. He made an iron boat, worked at an iron desk, built an iron pulpit, ordered that he be buried in an iron coffin, which he kept in his workshop (and out of which he would jump to amuse his comely female visitors), and is memorialized by an iron pillar he had erected in advance of his passing in a remote village in south Lancashire.