Полная версия

Bread Matters: The sorry state of modern bread and a definitive guide to baking your own

Bread Matters the State of Modern Bread and a Definitive Guide to Baking your Own

Andrew Whitley

Fourth Estate • London

To Veronica

Table of Contents

Cover Page

Title Page

Dedication

Introduction

Chapter One What’s the Matter with Modern Bread?

Chapter Two Does It Really Matter What Bread We Eat?

Chapter Three Taking Control

Chapter Four The Essential Ingredients

Chapter Five Starting from Scratch

Chapter Six First Bread and Rolls

Chapter Seven Simple Sourdough

Chapter Eight Bread – A Meal In Itself

Chapter Nine of Crust and Crumb

Chapter Ten Sweet Breads and Celebrations

Chapter Eleven Easy as Pie

Chapter Twelve Gluten-Free Baking

Chapter Thirteen Growing Old Gracefully

Notes

Index

Acknowledgements

Copyright

About the Publisher

INTRODUCTION

This book, as befits its theme, has been fermenting for quite a while. I started the Village Bakery in Melmerby in 1976, when the growing evidence that man could not live by white industrial bread alone was still being ridiculed by the scientific and medical establishments. At that time, none of the bakeries in nearby Penrith made a wholemeal loaf because there was ‘no demand for it’. All my first bread was wholemeal, made with flour stoneground at the local watermill. Partly to reassure myself that I wasn’t completely mad, I wrote a short history of bread on display boards to hang on the walls of our teashop. So began an attempt to understand why people have often chosen, or been forced, to eat bread that was not very good for them and how this might be changed now that we were discovering so much about the role of good food in public health.

Towards the end of the 1980s the upsurge of apparent allergy and intolerance to the main ingredients of bread presented me with a baking challenge. I had to go back to the first principles of fermentation to make loaves without wheat, gluten or baker’s yeast. It began to dawn on me that industrial bread might be making increasing numbers of people unwell because it was made too quickly. Since then, what little research has been done in this area has suggested that the longer bread is fermented, the more digestible and nutritious it gets.

I hope that something of the same effect can be detected in this book, in which I have tried to pass on the baking knowledge accumulated over 30 years. I have done so not only because making your own bread is one of the most satisfying things you can do but because, as the first chapters reveal, much of what you get in the shops should probably be avoided.

CHAPTER ONE WHAT’S THE MATTER WITH MODERN BREAD?

‘A technological triumph factory bread may be. Taste it has none. Should it be called bread?’ ELIZABETH DAVID, English Bread and Yeast Cookery (Allen Lane, 1977)

A very British loaf affair

Britons consume about eight million loaves a day plus countless rolls, sandwiches, pizzas and croissants. The baking industry is a model of industrial efficiency and British bread is amongst the lowest priced in Europe. Yet if you ask a Continental visitor what they think of living here, likely as not they will mention the lack of good bread.

We ourselves laugh at ‘cotton wool’ bread and put up with tasteless, mass-produced rolls in restaurants, canteens and takeaways. The better-off are tempted by ‘healthy’ loaves fortified with the latest fashionable nutrients, while the poor make do with bread sold primarily on price. If we care about bread, we have a funny way of showing it.

Behind the impressive production figures and the advertising hype of new product launches lies a revealing statistic. We eat less than half as much bread as we did 45 years ago. Well before fads like the low-carbohydrate Atkins diet, people were abandoning bread, and not only because they could afford other foods.

The startling possibility is that British consumers, without their knowledge, have been taking part in a flawed experiment. Back in the early 1960s, the national loaf was fundamentally redesigned. The flour and yeast were changed and a combination of intense energy and additives completely displaced time in the maturing of dough. Almost all our bread has been made this way for nearly half a century. It is white and light and stays soft for days. It is made largely with home-grown wheat and it is cheap. For increasing numbers of people, however, it is inedible.

This book uncovers what goes into the making of a modern loaf and charts the changes that the industry would rather we ignored. As technology finds ever more ingenious ways to adulterate our bread, so science is revealing the havoc this may be causing to public health. Recent research suggests that we urgently need to rethink the way we make bread.

If you are dismayed at the covert corruption of our daily food, you may agree with me that bread matters too much to be left to the industrial bakers. More and more people are taking control over their lives and health by making their own bread. If you are one of them, or would like to be, the second part of this book contains all you need to know in order to make your own bread, with real taste and integrity, bread you can trust and believe in.

Gut feelings

Why would hundreds of thousands of people stop eating bread and eliminate wheat from their diet? Cynics would say that the emergence of private allergy clinics and self-diagnosis by mail order might have something to do with it. For its part, much of the medical profession remains sniffy about the connection between diet and wellbeing. Yet scientific studies do show a surprisingly widespread sensitivity to wheat. This can take an extreme form known as coeliac disease, which is a serious reaction to gliadin, one of the gluten-forming proteins present mostly in wheat but also in smaller amounts in rye, barley and oats. Coeliac disease has a genetic component and, according to the Coeliac Society, may affect as many as one in 100 people in the UK. In his book The Complete Guide to Food Allergy and Intolerance (Bloomsbury, 1998, with L. Gamlin), leading allergy expert Professor Jonathan Brostoff describes coeliacs as ‘casualties of the slow adaptation process between the human race and wheat.’

It seems that sensitivity to gluten and wheat is like an iceberg. The visible part is composed of coeliacs whose condition is diagnosed by well-established tests and whose only treatment is a complete avoidance of gluten. Below the surface is a much larger group of people who have a sensitivity to wheat with varying degrees of severity, from mild discomfort when consuming bread to a condition known as ‘wheat-dependent exercise-induced anaphylaxis’1.

The strange thing is how recent all this is. Coeliac disease was first diagnosed in the 1950s, but widespread wheat intolerance emerged less than 20 years ago. At almost the same time, people started talking about an invasive strain of yeast called Candida albicans, which caused joint pain and digestive discomfort.

For a baker, this came as quite a shock. For 13 years or so I had been selling a range of wheat breads raised with yeast without once hearing about wheat or yeast intolerance or allergy. Suddenly people started ringing up asking for breads made without wheat or baker’s yeast – on the face of it, something of a tall order, given that the remaining ingredients of bread are just salt and water. Luckily, I was just developing a sourdough rye bread that contained no wheat and was raised using a spontaneous fermentation (lasting about 24 hours) of ‘wild’ yeasts present in the flour. Customers tried it and found that their digestive problems were eased. That was the first in a long line of products made without wheat for a market that had appeared from nowhere. Call it anecdotal (the word opponents use when your argument rattles them), but the evidence was clear: more and more people were buying products specifically because they didn’t contain wheat, or industrial yeast, or both. The bread on offer in the shops seemed to be making them ill.

Respect

British industrial bread commands little respect. This isn’t surprising when it is promoted with such mixed messages. Some loaves, described as having ‘premium’ qualities, seem barely distinguishable from others being sold at less than the price of a postage stamp. ‘Healthy-eating’ brands, adorned with images of nature and vitality, make detailed claims about the virtues of this or that added nutrient. But the big bakers keep quiet about nutrition when pushing their ‘standard’ loaves, which still account for over half of the market and are sold on price alone.

You might think that keeping prices down would be a good way to increase sales. But with bread, low cost and low quality have become so intertwined that conventional economics are turned on their head.

‘The Irish bread industry is driven by spread sheets and low prices,’ commented Derek O’Brien, head of the National Bakery School in Dublin, in 2004. ‘We produce some of the least expensive bread in Europe. But the result? Our bread consumption is one of the lowest in Europe. This is an appalling situation, particularly for the remaining number of smaller bakers, because their future is to a great extent dictated by the industrial baker.’

Many small bakers in the UK would recognise this situation. When low cost becomes below cost, an unseemly race to the bottom is inevitable. In the late 1990s I was told by the chief bakery buyer of one of Britain’s leading supermarkets that the cost of reducing the price of a standard 800g loaf of white sliced bread from 17p to 7p (in line with her main competitor) would be £400,000 a week – a sum that might have been better invested in promoting good food. Two of the main bakeries supplying the cheapest ‘value’ bread went spectacularly bust in 2004-5. Since then, the remaining large bakers have had some success in moving away from low-cost bread and even the supermarkets seem to have realised that loss-leading with something as vital as bread does them little credit. But it will take more than clever branding or a little soya, linseed and omega-3 to dispel the prevailing image of British bread culture as one dominated by pap.

If that seems a harsh judgement, take a look at what actually goes into your daily bread.

This is your loaf

In 1961 the British Baking Industries Research Association in Chorleywood, Hertfordshire, devised a breadmaking method using lower-protein wheat, an assortment of additives and high-speed mixing. Over 80 per cent of all UK bread is now made using this method and most of the rest uses a process called ‘activated dough development’ (ADD), which involves a similar range of additives. So, apart from a tiny percentage of bread, this is what we eat today.

The Chorleywood Bread Process (CBP) produces bread of phenomenal volume and lightness, with great labour efficiency and at low apparent cost. It isn’t promoted by name. You won’t see it mentioned on any labels. But you can’t miss it. From the clammy sides of your chilled wedge sandwich to the flabby roll astride every franchised burger, the stuff is there, with a soft, squishy texture that lasts for many days until the preservatives can hold back the mould no longer. If bread forms a ball that sticks to the roof of your mouth as you chew, thank the Chorleywood Bread Process – but don’t dwell on what it will shortly be doing to your guts.

This is Britain’s bread: a technological marvel combining production efficiency with a compelling appeal to the lowest common denominator of taste. It is the very embodiment of the modern age.

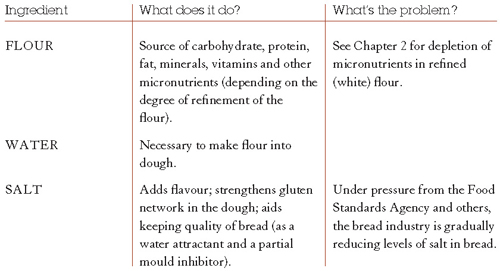

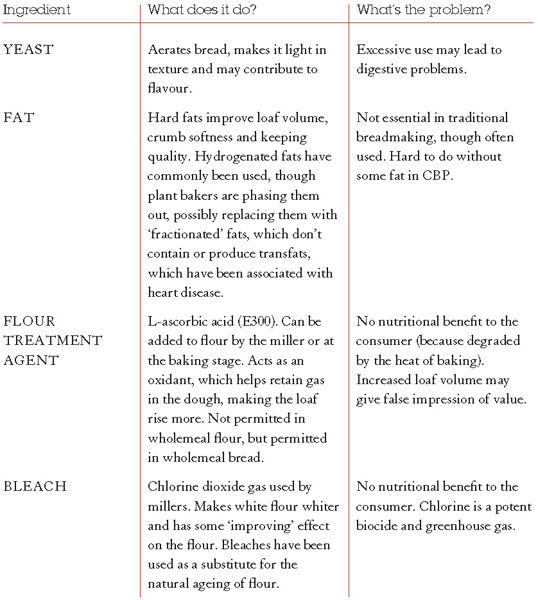

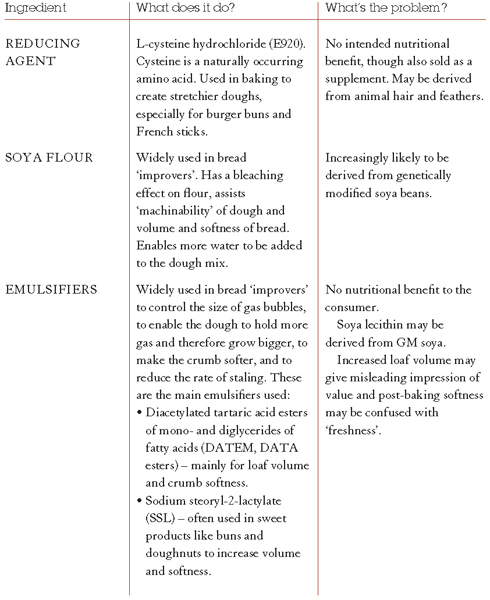

Below is a breakdown of a typical Chorleywood Bread Process loaf2. Only the first four ingredients in the table – flour, water, salt and yeast – are essential to make bread. In fact, even yeast (as an added ingredient) is unnecessary for breads made with natural leavens or sourdoughs. Bread made with these three or four simple ingredients was the basis of my bakery business for 25 years. So it is reasonable to ask: are all those other ingredients necessary? And, if not, what are they doing in our bread?

Read on and judge for yourself.

If you are unnerved by all the chemical names, you may be assured that the ingredients and additives listed above have received appropriate regulatory approval. Assured, but not reassured. The same could have been said 20 or 50 years ago, when the list would have contained chemicals that have since been banned. Safety assurance has a short shelf life. The development of modern emulsifiers, and especially of the newer bakery enzymes, was given considerable impetus by the withdrawal of the oxidising ‘improver’ potassium bromate, which after many years’ use was discovered to have carcinogenic potential (it is still used in some countries)3.

Moreover, there is a wider concern that makes it hard to accept today’s scientific consensus on food additives. New chemicals are evaluated on a primarily toxicological basis: feed a great deal of your chosen substance to laboratory rats for a limited period and, if they don’t keel over and die, it can be presumed safe for humans. However rigorous, such procedures clearly do not catch the effects of long-term low-level exposure to novel compounds or altered processes, not to mention the ‘cocktail’ effect of combinations of active agents too numerous or unpredictable to model in the laboratory.

Enzymes and the great ‘processing aid’ scam

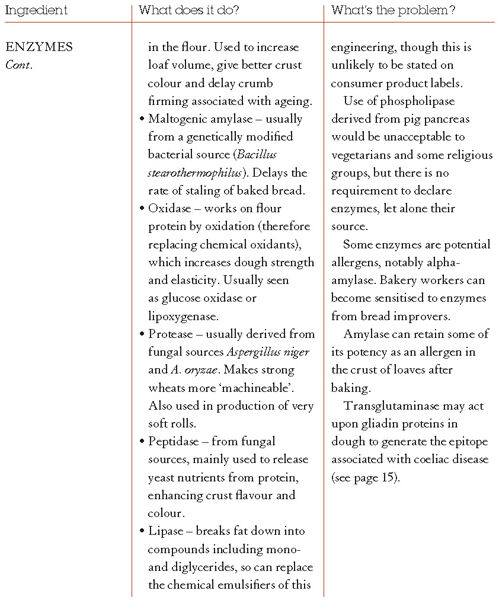

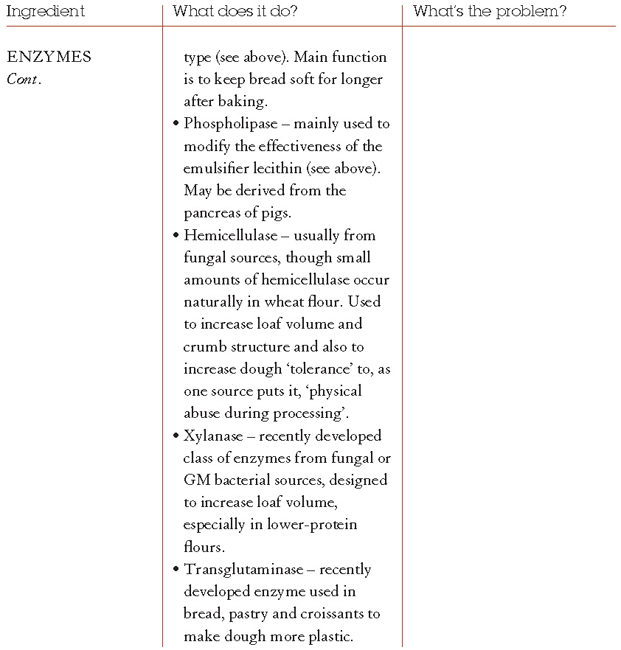

Enzymes are modern baking’s big secret. A loophole classifies them as ‘processing aids’, which need not be declared on product labels. Additives, on the other hand, must be listed in the ingredients panel. Not surprisingly, most people have no idea that their bread contains added enzymes.

An enzyme is a protein that speeds up a metabolic reaction. Enzymes are extracted from plant, animal, fungal and bacterial sources. Chymosin, for example, is the enzyme used to curdle milk for cheese making. It is either derived from rennet from a calf’s stomach or synthesised by genetic engineering. As you can seen from the table above, a whole host of enzymes is used in baking. Their status as processing aids is based on the assumption that they are ‘used up’ in the production process and are therefore not really present in the final product. This is a deception that allows the food industry to manipulate what we eat without telling us. In their own trade literature, enzyme manufacturers extol the ‘thermo-stability’ of this or that product – in other words its ability to have a lasting effect on the baked bread.

Manufacturers have developed enzymes with two main objectives: to make dough hold more gas (making lighter bread) and to make bread stay softer for longer after baking. As the table shows, many bakery enzymes are derived from substances that are not part of a normal human diet. Even if such enzymes are chemically the same as some of those naturally found in flour or bread dough, they are added in larger amounts than would ever be encountered in ordinary bread.

And now the safety of bakery enzymes has been radically challenged by the discovery that the enzyme transglutaminase, used to make dough stretchier in croissants and some breads, may turn part of the wheat protein toxic to people with severe gluten intolerance4. This development is important because it suggests that adding enzymes to bread dough may have unintended and damaging consequences. Surely no one can seriously suggest that bakery enzymes should be omitted from bread labels.

I think we should be suspicious of bakery enzymes for four additional reasons:

Enzymes can be allergens and should be identified on labels in the same way as the major allergen groups.

Failure to label enzymes prevents people making informed ethical choices about what they eat.

There is a fundamental dishonesty in treating enzymes as though they had no effect on baked bread when this is patently why they are used.

Judgements about ingredients should take into account the whole food; an enzyme may be harmless in itself but may be used to make an undesirable product.

Allergens

People have a right to know not just what is in their food but how it has been made. Some people need to know what is – or may be – in processed food because consuming the wrong thing may make them ill. Many food labels now contain advice designed to warn consumers not just about the actual content of the product in question but also about the possibility of contamination by potential allergens from the production environment.

But here’s a puzzle. Some allergens (peanuts, sesame seeds, gluten, lactose etc) have celebrity status, rightly, because of their potential for serious harm. Others, while known to specialists and sufferers, never make the charts. Amylase is one. Alpha-amylase is an enzyme naturally present in wheat in amounts that vary with variety and growing and harvesting conditions. Millers routinely add it to flour to make a more consistent product. It is also present in some compound bread ‘improvers’.

Amylases are known to cause allergic reactions in some people5. There is an occupational health risk to bakery workers if enzymes get into the atmosphere, where they are breathed in and can cause asthma. But recent research has shown that up to 20 per cent of the allergenicity of fungal alpha-amylase can survive in the crusts of bread6 (perhaps we should revise the old adage about eating up your crusts; they may do more than make your hair curl). So, while amylase allergy is clearly not an issue on a level with nuts or gluten, it exists and may be exacerbated by the addition of fungal amylases to flour and bread.

Ethical choices

It is not just a question of potential physical discomfort (or worse). As the controversy over genetically modified organisms (GMOs) in the late 1990s demonstrated, the way food is produced is of growing concern to many people – from the biological integrity of seeds, through farmers’ rights and animal welfare, to the impact on the physical and social environment. In other words, people may make moral judgments about provenance and production methods, even if these appear to have only a marginal bearing on the nature of the actual food they ingest.

For the food enzyme industry, all of nature is a chemistry set. No organisms are too exotic or repulsive to be investigated for possible active agents. As can be seen in the table above, the dough that goes into a loaf of standard factory bread may contain the strangest stuff – a reducing agent derived from animal hair or feathers, or enzymes from the pancreas of a pig. It may come as something of a shock to a Muslim or a Jew or a vegetarian that their daily bread is produced using animal by-products. It is possible that little or nothing of the original substance survives the baking process. But that isn’t the point. Bread has been made using an ingredient or process that some people find offensive. If you don’t know what’s gone into your bread – in the fullest sense of those words – how can you exercise any meaningful choice over whether to eat it or not?

‘Choice’, of course, is the mantra intoned by private business to promote product proliferation and by government to justify the intrusion of free-market economics into social provision. It is ironic therefore, that in their reluctance to declare what really goes into bread industrial bakers inhibit the exercise of informed choice and the regulatory authorities connive with a labelling regime that is geared more to commercial convenience than to true transparency.

Dishonest claims

We are entitled to ask why there is no requirement to tell people exactly what enzymes are put into our daily bread. European law is under review and may require processing aids to be treated like additives and declared on labels, but the new rule will not require bakers to give any more detail than the single word ‘enzymes’. What earthly good is that to consumers? Does it tell them that the enzyme added is alpha-amylase, to which some people are allergic? Does it alert them to the fact that the enzymes in question may include transglutaminase, which can turn wheat protein toxic for people sensitised to gluten? No, it does not.

In other words, we will move from the current state of total secrecy to one of bogus transparency where the information divulged is completely inadequate; it will be transparent only in the sense that you will be able to see right through to the information void on the other side. You don’t have to be a conspiracy theorist to wonder whether there’s something they don’t want us to know.

Cumulative effects

It is perfectly possible that a particular enzyme is ‘harmless’ in isolation, in terms of both toxicity and its functional effect in specific doughs, but the process in which it is a small element may produce bread with raised allergenicity or diminished nutritional status and ultimately, therefore, less healthy people. The challenge to industrial bakers is twofold:

Can they be sure that all bakery enzymes are safe?

Does their use produce the best possible bread?

On safety, the transglutaminase issue suggests that we need a more searching regulatory process and a considerably more precautionary approach.

On quality, it all depends how the word is defined. Rather than trade insults across the barricades of personal preference, it is worth asking what the makers of bread with added enzymes are actually trying to achieve: a saleable product or good food? Enzymes are used not for any nutritional benefit to the consumer, but to make it easier to produce bread on an industrial scale, to maximise loaf volume, to soften crumb texture and to maintain that softness for as long as possible. The net result is often a loaf of degraded nutritive value.

So there it is: your standard British loaf, made with all sorts of things you didn’t know were in it. Do people increasingly find modern bread not to their taste because of all these additives and ‘processing aids’? Perhaps. But the changes in bread since the 1960s go deeper. They affect almost every aspect of how it is made. Each change may have had its own logic at the time but together they have left us with bread that may be fundamentally flawed.