полная версия

полная версияNature's Teachings

“Serpents have been regarded as animals degraded from a higher type, but their whole organization, and especially their bony structure, demonstrate that their parts are as exquisitely adjusted to the form of their whole, and to their habits and sphere of life, as is the organization of any animal which we call superior to them.

“It is true that the serpent has no limbs, yet it can outclimb the monkey, outswim the fish, outleap the Jerboa, and, suddenly loosening the coils of its crouching spiral, it can spring into the air and seize the bird upon the wing: all these creatures have been observed to fall its prey.

“The serpent has neither hands nor talons, yet it can outwrestle the athlete, and crush the tiger in the embrace of its ponderous overlapping folds. Instead of licking up its food as it glides along, the serpent uplifts its crushed prey, and presents it, grasped in the death-coil as in hand, to its slimy, gaping mouth.

“It is truly wonderful to see the work of hands, feet, and fins performed by a modification of the vertebral column—by a multiplication of its segments with mobility of its ribs. But the vertebræ are especially modified, as we have seen, to compensate, by the strength of their numerous articulations, for the weakness of their manifold repetition, and the consequent elongation of the slender column.

“As serpents move chiefly on the surface of the earth, their danger is greatest from pressure and blows from above; all the joints are fashioned accordingly to resist yielding, and sustain pressure in a vertical direction; there is no natural undulation of the body upwards and downwards—it is permitted only from side to side. So closely and compactly do the ten pairs of joints between each of the two hundred or three hundred vertebræ fit together, that even in the relaxed and dead state the body cannot be twisted except in a series of side coils.”

The upper right-hand figure represents a portion of the shell of an Echinus, or Sea-urchin, together with two of the spikes.

The reader will remember that in the description of the Heart-urchin, and the mode in which it dug its way into the sand, the peculiar mobility of the spines was mentioned. How that mobility is produced we shall now see.

If a living Sea-urchin can be procured, and placed in a glass vessel filled with sea-water, it will at once be seen that its surface is thickly covered with spines. In some species these spines are as thick as ordinary drawing pencils; but in most of those which are found on our shores they are very slight, and scarcely longer than darning-needles. They are in almost perpetual motion, and generally have a sort of revolving movement, the base being the pivot.

Now, if we take a dried shell of the Sea-urchin, we shall find that the spines will come off with a touch, and, indeed, to preserve one with all the spines complete is a most difficult business. Let us, therefore, pull one from its attachment, and examine its base. This will be found to be swollen into a cup-like form, as seen in the illustration; and, if we look at the spot whence it came, we shall see that there is a little, rounded, polished prominence, exactly fitting into the cup, just as the ball of the human thigh-bone fits into the acetabulum. It has also its ligament to keep it in its place, and its same set of muscles that move it, and is altogether a most wonderful piece of mechanism. There are in some species of Echinus about four thousand of these spines.

The legs of an insect afford excellent examples of the ball-and-socket principle, the socket being on the body, and the ball on the base of the leg. Some of our largest insects—such, for example, as the common Stag-beetle—exhibit this principle very well. I have now before me a Stag-beetle which has been dead for many years, and is quite dry and hard. Yet I can rotate the legs almost as freely as if the beetle had been just killed, so easily do the joints work. Even the antennæ, which are affixed to the head by a similar joint, move about by their own weight on merely changing the position of the insect.

These are only a few of the many natural examples of the Ball-and-socket joint, but they are sufficient for our purpose.

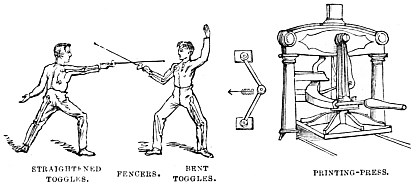

The Toggle or Knee JointAnother most useful invention now comes before us, called the Toggle-joint, or Knee-joint, the latter name being given to it on account of its manifest resemblance to the action of the human knee.

This joint is shown in the illustration. It consists of two levers, jointed together at one end, and having the other ends jointed to the objects which are to be pressed asunder. It will be seen that if the centre of the Toggle be pushed or pulled in the direction of the arrow, so as to straighten the levers, the amount of pressure upon them is enormous. Such an apparatus as this combines simplicity and power in a wonderful manner, and is greatly used in machinery, especially in presses, where the force is required to be great, but not of long duration.

An ordinary two-foot rule, when bent, affords a good example of the Toggle-joint, and will exert a wonderful amount of force.

The illustration represents one of the common printing-presses that are worked by hand. When the workman draws the handle horizontally, he causes the two portions of the Toggle to approach a straight line. The upper half of the Toggle being jointed to the fixed beam above, and the other half to the movable plate or “platen” below, it is evident that the latter will be pressed downwards with enormous force. Indeed, so great is the power of this instrument, that a man of moderate strength can exert a pressure of many tons.

We now proceed from Art to Nature, and take first the human knee, being the joint from which this piece of mechanism has derived one of its names.

If the reader will look at the figure of the fencers, he will see that the arm and leg are both Toggle-joints. In the one who is standing on the defence they are bent, and in the other, who has just made a longe, the Toggles of the right arm and left leg are straightened. It is by the straightening of these joints, and not by the action of stabbing, that the rapidity and force of a thrust are achieved.

It is just the same in boxing. No one who has the least knowledge of sparring strikes a round-handed blow, for, putting aside the ease with which it is parried or avoided, it has scarcely any force in it. When a boxer hits “straight from the shoulder,” he not only straightens the Toggle-joint of his left arm, but that of his right knee also, so that the force of the blow comes quite as much from the leg as the arm.

It is by the right use of this joint that a small man, provided he be an expert boxer, will easily conquer an ignorant opponent who far surpasses him in size and weight. I have seen in a sparring-match a man not only knocked down, but fairly lifted off his feet, by a blow from a smaller opponent. The blow took effect under the chin, and, as the boxer hit exactly the right moment in straightening both limbs, a very great force was exerted with little apparent effort. I do not know which of the two combatants was the more astonished, the one to find himself on his back without exactly knowing how he got there, and the other to see his antagonist prostrate without exactly knowing how the thing was done.

The jointed apparatus by which the heads of carriages are raised or lowered is a good example of the Toggle, and exemplifies the force which a comparatively slight piece of machinery can exercise.

Another form of the Toggle-joint is the process called by sailors “bowsing” of rope. If a rope be fastened at both ends, and then pulled in the middle, the ends are drawn forcibly towards each other. This plan is mostly adopted in getting up sails. When a sail, say the mainsail of a cutter, has to be hoisted as far as it will go, the last few inches are always very obstinate. The word is then given to “bowse.” The rope, or haulyard, is no longer pulled at the end, but a turn is taken round the cleat, so that it does not give way. The rope is then forcibly pulled away from the mast, when up goes the gaff a little higher. In this way, by repeated bowsings, the gaff is coaxed, so to speak, up the mast, and forced into its place.

Some of the leaf-rolling caterpillars act in a similar manner, by alternately bowsing and shortening their lines. As, however, their mode of working will be described under another heading, we will say no more of them at present.

CHAPTER II.

CRUSHING INSTRUMENTS.—THE NUT-CRACKERS, ROLLING-MILL, AND GRINDSTONE.—PRESSURE OF ATMOSPHERE.—SEED DIBBLES AND DRILLS

Importance of Leverage in Crushing Power.—Nut-crackers a Lever of the Second Order.—The Chaff-cutting and Tobacconists’ Machines.—Jaws of various Animals.—The Wolf-fish or Sea-wolf.—The Rolling-mill and its Action.—Gunpowder-mills and Granulating Machine.—The “Jacob’s Ladder.”—The Mangle and its various Adaptations.—The Grindstone.—Primitive Grindstones of the Savage Races.—The Kafirs and the Inhabitants of Palestine.—Ceasing of the Millstone.—“Facing” of Millstones.—Tusk of the Elephant and its Structure.—Its Facings always preserved.—Power of Self-renewal.—Pressure of Atmosphere.—The Napier Coffee Machine.—The Cupping Instrument.—The Pneumatic Peg.—The Magdeburg Hemispheres.—Plane Surfaces of Glass or Metal.—Suckers of the Cuttle-fish.—Foot of the Water-beetle.—The Limpet.—The Star-fish and its Mode of Progression.—The Sucking-fish and the Fables connected with it.—Its real Structure.—Modification of the Dorsal Fin.—The Gobies and Lump-fish.—The Gecko and Tree-frog.—The Lampern and the Medicinal Leech.—Seed Dibbles and Drills.—Labourers versus Machinery.—Natural Dibble of the Grasshopper.—The Daddy Long-legs.—Drills and Dibbles of the Ichneumon-flies.—A wonderful Specimen from Bogotá.—The Pelecinus and its Mode of laying Eggs.

Crushing InstrumentsAS we are on the subject of leverage, we will take some examples of levers in Art and Nature, without, however, even attempting to exhaust the topic.

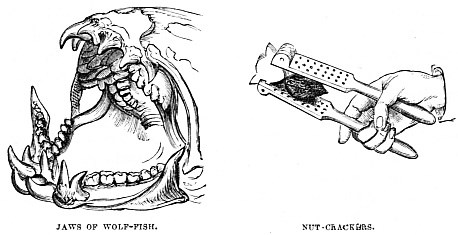

On the right hand of the illustration is shown a very familiar example of a lever, namely, nut-crackers, with a nut between them. This useful implement is simply an adaptation of levers of the second kind, the power being represented by the human hand, the weight by the nut, and the fulcrum being the joint of the instrument.

The common chaff-cutter, which is worked by hand, is another familiar example of this kind of lever, and so is the knife used by tobacconists in cutting cake Cavendish into threads, and by druggists for similar purposes. In these instruments the point of the knife is jointed to some fixed object, and becomes the fulcrum; the hand of the cutter supplies the power, and the weight is the object which is being cut. It will be seen that, by increasing the length of the handle, very great power can be obtained.

Exchanging the power for weight, we have in the common tongs, whether used for the coals or for sugar, a leverage of a similar character, the weight moving over a greater space than the power. A good example of this is to be found in the deltoid muscle of the human arm. The muscle, which furnishes the power, contracts about an inch, and, so doing, moves the hand over some forty inches of space. It has been well stated that if a man is able to hold in his hand, and with extended arm, a weight of twenty-five pounds, the muscle must be exerting a power of forty times as great, i.e. about a thousand pounds.

There is little doubt that, in such Crushing Instruments as have been mentioned, the idea has been taken from the jaws of sundry animals. We know, for example, that with ourselves, if we desire to crack a walnut or a filbert in our teeth, we always put it as far back as possible, so as to make the leverage as powerful as possible. No one would ever dream of cracking a nut with his front teeth, an act which would be very much like that of trying to break a piece of coal by pinching it with the tongs.

The left-hand figure of the illustration represents part of the jaws of the Wolf-fish, or Sea-wolf, as it is sometimes called, and a very wonderful crushing machine it is. The Sea-wolf (Anarrhicas lupus), sometimes called the Sea-cat, or Swine-fish, is tolerably common on our coasts, and, as it sometimes attains a length of seven feet, and is proportionately stout and muscular, the power of its bite may be estimated. The fish in question feeds chiefly on crustacea and hard-shelled molluscs, and is therefore furnished with an apparatus which can crush their shells. Extremes meet. The Sea-anemones, which are mere films of animal matter, and can be torn in pieces with the finger and thumb, can seize, swallow, and digest a crab or an oyster in spite of the thick and strong shells in which they are enclosed. So can the Sea-wolf, and fishes of a similar character. But nothing intermediate can touch them, and it is curious to reflect that such opposite means should produce a similar effect.

On reference to the illustration, the reader will see how exact is the parallel between the Nut-crackers and the Sea-wolf’s jaws, both being worked on the same principle, and both being furnished with a series of projecting points, which are used for the purpose of preventing the escape of the object which is to be crushed. The terrible grasping power of the crocodile, the dolphin, and other predacious creatures can be explained on the same principle.

The Rolling-millWe now come to another variation of the Crushing Machine, i.e. that in which the motion is constant, and not intermittent, as is the case with those machines which have just been mentioned.

Perhaps some of my readers may have visited those great iron-works in which huge masses of iron are rolled into plates of greater or less thickness, or are cut up into strips as easily as if they were butter.

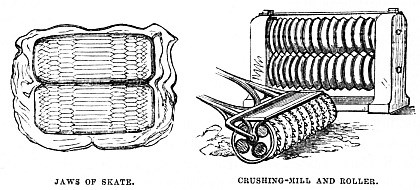

The mechanism is in its principle simple enough. The cylindrical rollers are placed nearly in contact, and forced towards each other by mechanical means, such as levers, screws, or springs, or all three combined. These cylinders revolve in opposite directions, and, if any object be placed between them, they draw it through them, and present it on the other side in a flattened condition.

Many years ago, one of my schoolfellows, who had been brought up entirely under the care of some maiden ladies, was visiting a workshop, and must needs put his finger between two revolving rollers. Of course the hand was drawn between them, and simply squeezed flat. The machine was instantly stopped, and the hand extricated; and the strange thing was, that the crushed and shapeless hand afterwards recovered its full power, though not its shape, and was able to touch the keys of the piano.

The whole process of the Rolling-mill is singularly interesting, whether it be used for large or small objects.

Supposing that the grooved rollers of the illustration were cut across so as to present a number of points, it is evident that anything which got between them would be bitten to pieces, each piece being of a tolerably uniform shape.

This plan is now adopted in the granulation of gunpowder. After the future powder has emerged from the hydraulic press in the form called “press-cake,” it was formerly broken to bits with wooden or copper mallets, and then placed in a very peculiar kind of sieve. This was shaped like an ordinary sieve, but the bottom was made of cowhide, pierced with innumerable holes. A round pebble was placed in the sieve, and, when the latter was violently shaken backwards and forwards, the powder was driven through the holes by the pressure of the stone, and was afterwards separated into its various degrees of fineness.

I have only twice seen this process, and confess to have been in a very nervous state on both occasions. The sieve is whirled about with enormous velocity, and the pebble flies round as if it were a thing alive. Let but a broken needle or a fragment of stone get into the sieve, or even let the stone itself break asunder, and there will be an instantaneous explosion, which will hurl the house, the machinery, and the workmen into unknown regions.

Now, however, the mode of granulating powder is radically altered. There is a series of double cylinders, such as shown in the illustration, and each of them has the ridges cut into teeth in regular order. Thus the first set of rollers or cylinders merely bites the press-cake into convenient pieces, though seldom of the same weight.

The press-cake, thus bitten to pieces, is passed through a series of cylindrical sieves, each graduated with the utmost accuracy, and being turned by means of machinery. Being set on a slope, the powder runs by its own weight down them, and all those particles which cannot pass through the meshes are poured out untouched at the lower end.

The portions which are too large to pass the openings of the first sieve are then handed onwards by means of a machine called a “Jacob’s Ladder,” which consists of a series of little vessels or buckets strung on a tape, and revolving over a couple of wheels. The first set of buckets takes the coarsely bitten press-cake to the second set of rollers, the teeth of which are comparatively small. Thence it is passed over to a third set, and so forth, until it is delivered in any quality of grain which may be required.

The modern Mangle, again, affords a good example of this principle. The old obtrusive, costly, and cumbrous Mangle, which was nothing more than a heavy box of stones upon rollers, has given place to the modern system of duplex action in rollers, and one of the old Mangles is not easily to be seen, unless it be worked as a curiosity. In fact, it is nearly as obsolete as the spinning-wheel, which yet may be seen in some of our country villages, where scarcely one per cent, of the population has ever been in a town, and many of them, the women especially, make it their boast that they have never been beyond the outskirts of their village.

This clumsy machine is now replaced by the very simple invention which has been in vogue for some years, and which can not only release, but regulate, the pressure at any moment, by means of springs, levers, and weights. This machine is, in fact, exactly the same as that which is represented in the illustration, except that the rollers are quite smooth. They can be adjusted to almost any amount of pressure by levers and weights which are attached to the upper roller, and, when the linen has passed through them, it has undergone the double operation of wringing and mangling. This disposition of the rollers has long been anticipated in the jaws of the Skate which crush to pieces the shells of the whelks, periwinkles, &c., on which the creature feeds.

The GrindstoneBeing on the subject of jaws and teeth as a mode of breaking to pieces objects which are placed between them, we will take those implements which grind to powder, or “triturate,” instead of breaking or flattening.

From the very earliest ages, and as soon as man had begun to discover the “staff of life,” the art of grinding naturally assumed an ever-increasing importance.

The first and most primitive mode of grinding corn and converting it into meal was that which was followed by Sarah, when she welcomed her husband’s guests, which we know, from internal evidence, was followed by the uncivilised races who formerly inhabited this island, and by many semi-savages of the present day.

Nothing could be simpler than the machinery used, and nothing could cause a greater waste of muscular power. Two stones were employed, a large one upon which the grain was placed, and a smaller which was held in the hands, and used for grinding the corn to powder, just as the painters of the last century used to grind their colours. The Kafirs of Southern Africa use this simple mill, and so exactly do they keep unconsciously to the customs of long-perished natives, that if one of their mills were buried for a few years and dug up again, it might be mistaken for one of the ancient “querns.” As the stone held in the hand was rounded, it naturally wore a rounded hollow in the lower stone, and this made the process of trituration easier. Perhaps some of my readers may have noticed that when a chemist makes up a prescription, and is obliged to reduce one of the ingredients to powder, he always does so by rubbing, and not by pounding, as is generally believed. He works the pestle round and round the mortar with a kind of twisting motion, and thus obtains a powder much too fine to have been produced by any amount of pounding.

The labour of this operation is necessarily very severe, and therefore the Kafir of the present day, as did his predecessors of the long-lost races, declines to do it himself, but hands it over to the women. In Palestine, as in other parts of the world, a simple mill has been invented, which takes away much of the labour, and, above all, releases the grinder from the obligation of leaning with her fall weight upon the upper stone. In this mill the stones are similar. The upper is moved backwards and forwards round a pivot, and the grain is passed between them by means of a conical aperture in the upper stone, which answers the purpose of our “hopper.”

In order to work this mill, two women are required, sitting opposite each other, with the mill between them, holding the same handle, and assisting each other in turning the stone backwards and forwards. No one who has not seen this operation can fully appreciate the force of the saying that “two women shall be grinding at the mill; the one shall be taken, and the other left.”

It is worthy of remark that, even at the present day, the custom of grinding corn is carried out in Palestine as it was so many centuries ago, and that it is repeated in Southern Africa among the Kafir tribes. In both parts of the earth the first sound of early morning is caused by the millstones of the grinding women, and the amount and duration of the noise afford a sure test of prosperity. Cessation of the millstones signifies adversity and a thin population, as has been said by a writer who lived not very far from three thousand years ago. Speaking of tribulation, he mentions that “the grinders cease because they be few, and that the doors shall be shut in the streets when the sound of the grinding is low.”

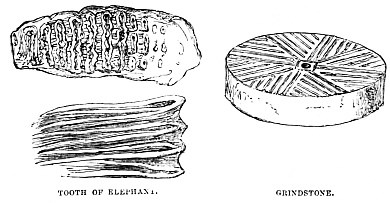

After awhile improvements were gradually introduced into the business of grinding, not the least of which was covering its surface with ridges, instead of leaving it entirely smooth, as it had been formerly. Millers of the present time know the value of these ridges, and the additional grinding power which this “facing” gives to a stone. One of these stones is represented in the illustration, so as to show the system on which the ridges and grooves are constructed.

Now, passing from Art to Nature, we find that the whole system of the millstone, its movement and its ridged surface, existed in the times when man had not yet come upon earth.

The reader is probably aware that among the tooth-bearing animals there are three types of teeth. First come the incisors, or cutting teeth, which occupy the front of the jaw, and find their fullest development in the rodent animals, such as the beaver, the squirrel, the rabbit, and the rat. Next them come the canine or piercing teeth, which are so highly developed in all the cat tribe. Lastly, there are the molar or masticating teeth, so called from a Latin word signifying a millstone, because their office is to grind food.

As it is with these last that we have now to treat, we will say nothing about the others.

The molar teeth find their greatest development in the Elephant, the structure of whose molars is exactly like that of our modern millstones. There is certainly one very great difference. When the surface of a millstone is rubbed away, the stone must be re-faced, and sooner or later is worn out altogether, and must be replaced with a new one. This, however, is not the case with the Elephant’s molar teeth, which not only keep their facing perfectly sharp, but have the faculty of renewing themselves as fast as they are worn away.