полная версия

полная версияThe Olive

The olives are placed in an alkaline solution, usually sodium hydrate as it is stronger in action than potassium hydrate. The strength varies with the different packers but is generally in the neighborhood of 1½%. After 6 to 8 hours, the lye is drawn off and the olives exposed to the air in order that they may oxidize and darken, since the lye removes some of the natural color. The operation is repeated with the same strength or less of lye solution and the fruit exposed to the air until examination of the pulp shows that the lye has penetrated to the pit. The lye solution is then replaced with clear water which is changed twice a day, until the lye and bitterness are removed, which requires from 4 to 8 days. The olives are then treated with brine solutions, starting with 1 %, and increasing the strength at intervals of about 2 days until about 4 % is used, when they are ready to be put in glass jars or cans and sealed.

The brine is used very weak at the start and gradually increased so that the osmotic action may be so controlled as not to cause the fruit to shrivel as it would if placed in a strong solution at the start. Some packers permit the olives to stay in the weak brine long enough for fermentation to take place as done with the imported green olives so as to develop an acid flavor. The more recent tendency, however, is toward packing them with the least possible change, and to depend upon the distinctive natural flavor of the fruit itself. A similar tendency toward retaining the natural color, rather than that induced by oxidation, might be advantageous.

If it be the intent to hold the olives in bulk, they are treated with increasingly strong brines until 10 to 12½% is used, the latter amount being required to carry them safely through the summer.

The process is modified in practise to suit the conditions, as variations in varieties of fruit, in temperature, and in the lye have to be considered. There are also variations in practise due to individual experience. During the time the olives are in the various solutions they are stirred frequently, so as to change their position in the vats, and also to change the solution in contact with them. The stirring was, and is done yet in some cases, by hand, with wooden paddles, which is laborious besides causing more or less damage to the fruit. Recently compressed air has been piped to the vats and directed into the solutions with sufficient force to keep the olives agitated. This method is said to hasten the action of the lye solutions with consequent improvement in the fruit. It also obviates the drawing off the solutions and the exposure of the fruit to the air, as a certain amount of oxidation takes place in the solution.

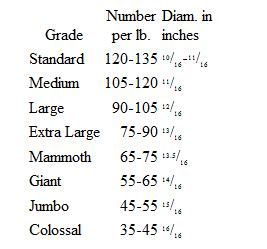

As the operators place the olives in the bottles or cans, the soft and defective ones are discarded. The containers are then filled with a 3 % brine at a temperature of 175 or 180 degrees F. The air is exhausted, during which the temperature is raised to 185 degrees, and the containers sealed, after which they are processed. The large olives in a 26 ounce glass jar are cooked for 50 minutes; extra large, 55 minutes; mammoth, 58 minutes; and colossal 60 minutes; at 240 degree F. in some factories, or for a longer period if processed at a lower temperature.

The time required for heat to penetrate to the center of an olive is longer than has been generally supposed. This was determined by carefully drilling into the pit, first with a fine drill and then with increasingly larger ones, until an eighth inch hole was made. The bulb of a small thermometer was inserted, and to prevent heat being carried to the bulb by means of the glass stem, sections of olives were placed around the stem immediately above the olive being tested, and tied securely. Jumbo olives at room temperature placed directly in a boiling bath required on an average fourteen and one-half minutes for the temperature to reach 209 degrees F., which is practically the maximum which can be attained under the conditions. When the olive was placed in cold water and the bath heated rapidly under conditions similar to home canning, the average time required to reach 209 degrees F. was 29 minutes. The former experiment represents a more favorable condition for heat penetration than prevails in factory operations, and the latter probably the least favorable, but both show that in the ordinary process all parts of the olive do not reach the high temperature supposed to be produced by that of the bath for more than a few minutes.

At the University of California ripe olives have been canned without brine. After pickling, the olives have been placed in 3 % brine for several days, then heated in the brine to about 180 degrees F. after which they are taken from the brine, put in the bottles or cans, sealed, and processed. No shrinking, wrinkling, softening, nor change in color is said to take place. By the elimination of the brine in the container, there results a saving in freight of 31.5 % with cans and 16.6 % with bottles.

The history of the olive and its method of preparation show that no organisms pathogenic to man are normally present and that if such organisms be associated with it in any way, it must be from the outside and through local infection.

More care is required in processing at high temperatures, than at boiling. A high internal pressure is developed inside the cans or jars, due to the expansion of the contents and of the enclosed gases, which has a tendency to loosen or blow off the covers. This tendency may be overcome by applying air or water pressure on the outside of the cans or jars to counteract that generated within. This is done while they are inside the retort and by means of automatic pressure controllers. There is no essential difference in the sterilizing and cooling of tin cans and glass jars, both forms of containers are responsive to treatment with high temperatures and both require proper care and handling. As with pickled olives, however, glass jars permit the purchaser to see the size and the condition of the fruit.

The canning of ripe olives in California was originated by F. T. Bioletti, zymologist in the University of California, and came about through an investigation in 1889 on the spoiling of olives. When pickled olives were held, the quality deteriorated in some of them, they softened during the summer, and seldom remained in an edible condition for a year. As a result of his experiments on methods of keeping, he found that the olives could be sterilized in sealed containers and be kept in edible condition indefinitely. The commercial application of the method and the popularizing of the ripe olive is due to Mrs. Freda Ehmann, a pioneer olive grower, who applied scientific methods, with marked success, to both the development and canning of the olive.

The sustained scientific work along developmental and preserving lines in this country, has been done mainly by Wickson, Bioletti, and Cruess of the state university staff to whom great credit is due for the advancement made. Many improvements have naturally been made by manufacturers in the preparation of the ripe olive but are held by the factories for their own use solely.

Recently Cruess has developed methods for treating the ripe olive with aerated hot solutions which have permitted the preliminary treatments to be done in 3 to 6 days, instead of as formerly in 3 to 6 weeks. The methods promise to be of great economic value, and have been patented for the benefit of the public.

The olives which are too small or misshapen to be used in the regular pack are sometimes used for other purposes besides oil extraction in which size and appearance are not factors. The flesh is ground and seasoned and thus furnishes a mixture for relishes and sandwich filling, or the flesh is mixed with pickled cucumbers, capers, pimiento, tomato, etc., in various combinations for the same purposes or to flavor sauces. The appetizing ways in which olives may be used alone or in combination, and the attractive dishes which can be prepared from them are endless.

A preparation which has considerable vogue with lovers of ripe olives is to take the olives from the brine some hours before using and cover them with olive oil. This preparation may be further enhanced by rubbing the dish before using, with a cut clove of garlic. The use of aromatics in the preliminary preparation, then packing in oil, as done by the Greeks, Italians, and Spaniards, with some of their best olives, produce very fine products that are far ahead, in both flavor and food value, of the ordinary preparations.

The olive, though used almost exclusively as a relish or appetizer in this country, is a valuable food. This is true for both the green and the ripe, the difference in the two not being so great as is frequently claimed. The pickled green olive has supplanted the cucumber pickle to a very considerable extent in the trade. The canned ripe olive is distinctive and depends upon an entirely different quality for its favor. As long as the present prices prevail, they can not be considered on the basis of staples or in competition with many other foods in furnishing nutritive elements.

The flesh of the American olive consists of about 80 per cent of the fruit, and of this the solids average 38 per cent, oil 25 per cent, and protein 1.2 per cent.

In spite of the fact that olives have been used as a food from time immemorial, very little systematic analytic work seems to have been done on the whole fruit in the various stages of maturity and in determining the effect of the various treatments for the removal of the bitterness. Much of the analytic work has been devoted to analyses of the oil and to methods for determining adulteration. The methods followed in this country and abroad are not the same and the results are therefore not comparable. It seems strange that so old and so commercially important a fruit has not been investigated to the minutest detail.

It is stated that the olive on reaching full size increases in weight and oil content as it matures, the various stages being approximately determined by the change in color from green to yellow, red, and finally black. When, however, one finds analyses of typical fruit of one variety and from the same place which show the flesh of the green olive to contain 23.55 per cent; yellowish green, 20.37 per cent; red, 27.35 per cent; and purple to black, 24.89 per cent oil, it discounts the color value. Other available analyses show similar discrepancies between the chemical composition and the color test as indicative of maturity. Variation in composition occurs in the same variety of fruit grown in different places as well as in the different varieties and, as with other fruits, one is dependent upon the skill of the packer in selecting raw stock and in handling it in the process of manufacture, for the quality of the article received. It is only natural to expect that a product containing so much oil and subjected to the action of lye, might be greatly changed during its preparation. The data available, however, does not sustain this premise, but shows that very little change actually takes place.

1

H. C. Newcomb, former vice-consul to Spain.