полная версия

полная версияExperiments on the Spoilage of Tomato Ketchup

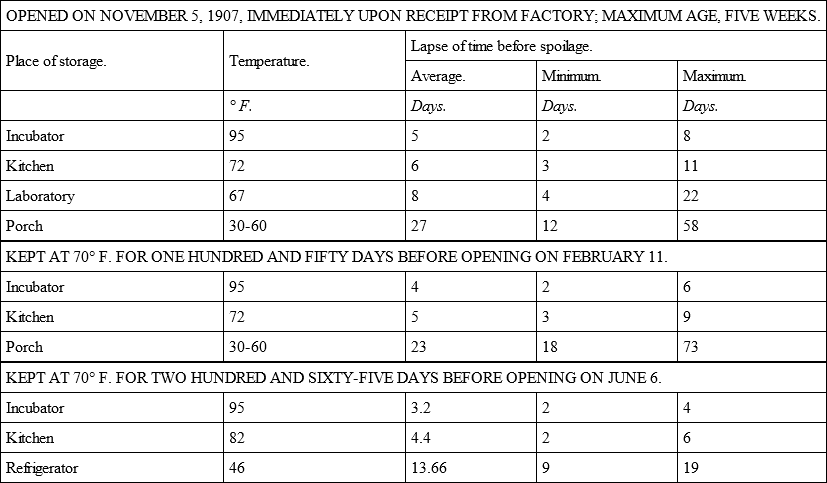

The results showed that the differences in the time and temperature of processing had little, if any, effect in checking the spoilage; neither did the use of acetic acid or oil extracts. The most important precaution in checking the spoilage after opening seems to be to keep the ketchup cool. This is shown by the average number of days which elapsed before spoilage occurred in the sets kept under different temperature conditions. For those kept in the kitchen the average number of days was six, the minimum three, and the maximum eleven. Those in the incubator kept for an average of five days, with a minimum of two days, and a maximum of eight. Those in the laboratory had an average of eight days, the minimum being four days and the maximum twenty-two. Those kept in the porch lasted on an average twenty-seven days, a minimum of twelve days, and a maximum of fifty-eight.

These figures show the definite relation of temperature to spoilage under the conditions of ordinary use. In making the observations, the metal cap was removed each day, but no ketchup was poured off. The spoilage in all cases was due to mold, and usually this formed in the neck of the bottle where the ketchup had splashed, or at the junction of the ketchup with the bottle. The spoilage was recorded as soon as the slightest growth appeared. In actual use if the neck were wiped out when the ketchup had been used and a growth of mold removed on its first appearance with some of the proximate ketchup the time before spoilage occurred could be prolonged. In these experiments the attempt was made to determine how soon growth appeared under the various conditions of temperature named.

The unopened bottles of ketchup were kept in a basement room, the temperature of which is fairly constant, being about 70° F. This is approximately the condition in a grocery where the ketchup is kept on the shelves. Another set of samples from the run of September, 1907, was opened February 11, 1908, to determine if storing in a warm room before opening had any effect on the length of time preceding spoilage. Four bottles were taken from each of the first 9 experiments to make up each of three sets, one of which was kept in the kitchen, one in the incubator, and one in the porch, making a total of 108 bottles. The average number of days for those kept in the incubator was four, the minimum two, and the maximum six. The average number of days before spoilage in the kitchen was five, the minimum being three and the maximum nine. Those kept in the porch gave an average of twenty-three days, the minimum number being eighteen days and the maximum seventy-three days. Thus it is seen that the ketchup lasted nearly five times as long at a temperature of 30° to 60° F. as it did at 72°; and also that when ketchup is kept in a warm place before opening, spoilage occurs somewhat sooner, the average for the fresh samples opened under the same conditions being one day more with the incubator and kitchen samples and four days more with the porch samples.

A third set of bottles of the ketchup was opened on June 6, 1908, or two hundred and sixty-five days after manufacture. They had been kept in a basement at a temperature of about 70° F.

One set was placed in the incubator at a temperature of 95° F., one set in the kitchen at about 82° F., and one set in the refrigerator at 46° F. The weather was warm and the conditions favorable to the spoilage of fresh foods. The minimum time for spoilage in the incubator was two days, the maximum time four days, and the average time three and two-tenths days. The minimum time in the kitchen was two days, the maximum time six days, and the average time four and four-tenths days. The minimum time in the refrigerator was nine days, the maximum time nineteen days, and the average time thirteen and sixty-six one-hundredths days.

These data are grouped in the following table for easier comparison:

Time of spoilage of ketchup at different temperatures after opening.

SPOILAGE OF UNOPENED KETCHUP

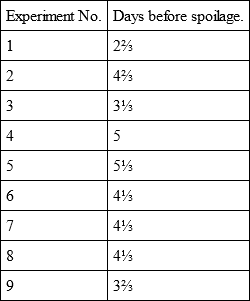

Another test was made to determine whether the ketchup would spoil when kept in a warm place, but not opened. Three bottles from each experimental batch were placed in the incubator November 7, 1907, and were kept there until December 23, 1907 – forty-six days – and in that time there was no sign of spoilage. They were then opened and kept in the laboratory; the average number of days before spoilage occurred is indicated in the following table:

Average number of days before spoilage of ketchup after opening (kept 46 days at 95° before opening).

It will be observed that these samples spoiled in about the same length of time as the bottles opened in February and tested in the incubator, so that similar results were obtained by keeping unopened ketchup one and one-half months at 95° F. and keeping it five months at 70° F. From the results of the experiments it is evident that the ingredients of the ketchup in the proportions used are not antiseptic, and it is also apparent from the number of organisms found and the rapidity of their multiplication that ketchup is a good, nutritive medium. Yeasts and molds are the predominating organisms, and, as the ketchup is acid and also contains sugar, and these organisms are found on tomatoes in the field, their predominance in the ketchup is explained.

SPOILAGE OF MARKET BRANDS

To determine the keeping properties of the ketchup on the market, various brands were obtained from the grocery stores. In the majority of cases nothing was known of the ingredients or methods of manufacture, except what appeared on the labels. No date of manufacture was given, and in some cases the dealers did not know the age of the product.

There were 104 bottles of ketchup opened to find out how long they would remain in good condition. These were kept in the laboratory, though the temperature was higher than that at which ketchup should be held. Of the 104 bottles there were 66 without preservative, according to the labels, 46 of which spoiled. Of the 20 which did not spoil, 2 formed crystals of benzoic acid on the covers of glass dishes during evaporation. Of the 39 which, according to the labels, contained sodium benzoate, 15 spoiled. The bottles of unspoiled ketchup after remaining in the laboratory for about a month were placed in the incubator at 95° F. for three weeks, and were then taken out, and have been left in the laboratory since. The metal cap had been taken off frequently for observation, and the ketchup exposed, but the treatment did not cause them to spoil.

The average number of days after which spoilage occurred for the 46 bottles without preservative was about fifteen, the minimum number being four days, the maximum number ninety-four days. The average number of days preceding spoilage in the case of 15 bottles with preservative was twenty-four days, the minimum number being three and the maximum sixty days. The majority of these had 0.1 per cent of sodium benzoate present; the others had a smaller amount, according to the manufacturer’s label. These data are not at all conclusive and further work on material of known history will be necessary.

STERILITY OF KETCHUP

To determine the sterility of ketchup, cultures were made from 77 of the bottles. The method used was to wipe the bottles and cork stoppers with a damp towel and then remove the cork. The cork puller which was used grasps the neck of the bottle in such a way as to cover the opening and remove the cork without the inrush of air that occurs when the ordinary corkscrew is used. A flame was then passed over the mouth of the bottle, after which the upper layer of ketchup was poured out, so as to discard any material which might have been contaminated in handling. Tomato gelatin was used as a medium and cultures were made in petri dishes.

There were 17 plates on which no organisms developed, indicating that the ketchup was sterile. Of the 60 plates having organisms, 54 had molds, 22 of these having molds alone; 21 plates had yeast-like organisms, 3 plates having these only; 29 plates had bacteria, 4 having bacteria alone. Sometimes a plate would have only one form of organism, but more often there was a mixture present. Of 15 plates having only one form of organism, 3 had yeast alone, 2 bacteria alone, and 10 had mold alone. Of the 77 bottles of ketchup from which the inoculations were made, 41 were without and 36 with preservative, and of the 17 sterile ketchups, 8 contained sodium benzoate and 9 were without preservative.

A considerable part of the experimental ketchup proved not to be sterile. The organisms present were of the class which require oxygen for their growth and therefore they had only been arrested in their activity. No growth could take place so long as the air was excluded and therefore no spoilage could occur. When the cork was drawn, the organisms could grow and cause spoilage, and this is a much more potent factor than the entrance of germs from without. Bottling and sealing the ketchup quickly while hot so completely excludes the air that only a few colonies of yeast or mold may be found on subsequent microscopical examination. Filling at a low temperature and corking while cool allows sufficient air to remain incorporated in the ketchup and neck of the bottle to permit a considerable growth of the organisms and a product derived from good stock may thus acquire the appearance of ketchup derived from partially decayed material. A ketchup in which bubbles of air are incorporated in filling may show a growth of mold at each bubble throughout the mass. The foregoing statements apply to ketchup containing sodium benzoate as well as to the non-preservative goods of the character used in these experiments.

EXPERIMENTS WITH PRESERVATIVES

SODIUM BENZOATE

The preservative in general use in ketchup is sodium benzoate. Salicylic acid is used, but only to a limited extent. The amount of sodium benzoate used, according to the labels, varies from one-sixteenth to one-tenth of 1 per cent; but on some labels the amount is not stated. Experiments were made to determine the amount necessary to check the spoilage of ketchup.

Two organisms, a mold and a yeast, were selected on which to make the tests. The mold was the ordinary blue mold, Penicillium, which was present in many of the brands of ketchup and is found commonly on acid foods. It was selected on account of its prevalence and resistive power. The yeast was obtained from ketchup and was also a vigorous grower, forming a thick, wrinkled film on various media. Any effect on the growth of the yeast could be seen readily in its manner of forming the film.

Portions of tomato gelatin to which 0.1, 0.5, 1, and 2 per cent, respectively, of sodium benzoate were added, were first inoculated with the mold. There was no development in those containing 1 and 2 per cent; a retarded development resulted in that containing 0.5 per cent, and the growth when 0.1 per cent was used was nearly normal, showing very little difference from that in the gelatin without sodium benzoate.

Ketchup was next tried as a medium, but the amount of benzoate was reduced to one-sixteenth, one-twelfth, and one-tenth of 1 per cent, as it was thought that some of the other constituents of the ketchup were antiseptic to a slight degree. The growth in the ketchup was irregular, though the benzoate checked development in all. Equal amounts of benzoate were used in tomato bouillon, with practically the same results as in the ketchup. The development was checked in all, and in some plates one-sixteenth of 1 per cent seemed to be fully as efficacious as one-tenth of 1 per cent. When the mold was examined under the microscope, the filaments were found to be much swollen and distorted in shape, and filled with a coarsely granular protoplasm, containing much fat, as indicated by the blackening with osmic acid. The culture containing the mold which gave the least development seemed to show the least distortion and swelling of the filaments.

The results indicated that in using sodium benzoate as a preservative there is uncertainty as to results, even when using the maximum amount allowed – one-tenth of 1 per cent. They also indicated that this preservative had an injurious effect on the living matter of the mold. (See Pl. II; compare with normal growth, Pl. I.)

SALT

The effect of salt in checking development was tested by using tomato bouillon as a medium and adding 5, 10, 15, 20, 25, and 30 grams of salt, respectively, to 100 cc. These were inoculated with the mold. The 5-gram solution seemed to have no effect on development. When 10 grams were used growth appeared as soon as in the bouillon without salt, but was not so extensive. In the 15-gram solution growth was retarded four days, and most of that which did develop remained submerged, the mold growing normally on the surface. With 20 grams the growth was five days slower than the normal in starting, and after that there was only a slight development. In the 25-gram solution, the growth started at the same time as when 20 grams were employed, but remained stationary, while with the 30-gram solution, no development occurred.

The yeast was checked slightly by 5 grams, and very materially by the 10-gram solution, as it required two days for a thin, delicate film to form, whereas in ordinary solutions a rather thick film is formed within twenty-four hours or even in less time. There was no development in the 15-gram solution.

SUGAR

The effect of sugar was tested on both the mold and the yeast by adding it to tomato bouillon. It was supposed that a low percentage of sugar like the salt would plasmolyze the cells, and in this way check growth, but it seemed to have no effect until the amount was increased to 25 grams per 100 cc of bouillon. In this solution growth appeared as soon as with the weaker solutions, but there was a smaller amount. In the 25 to 40 gram solutions there was less development as the amount of sugar increased. In the 70 and 75 gram solutions growth was delayed one day in its appearance. In the 80, 85, and 90 gram solutions growth was delayed two days, the colonies growing submerged at first, but after a time forming on the surface. The mycelium remained very thin, but a thick layer of spores formed. From this point on the amounts were increased by 10 grams up to 200. The development became slower and less successively until 170 grams were added. In this case a small colony appeared on the surface in seven days, but seemed to grow less after that. The solutions were held, and in time crystals separated from the thick sirups. After two months dry-looking colonies developed along the edges, forming a ring, and some formed on the surface, these occurring also in the flasks containing 170, 180, 190, and 200 grams of sugar per 100 cc. The colonies were a dull greenish drab in spots, the remainder being white.

For the yeast the 80-gram solution of sugar was the strongest in which any development took place.

SPICES

Experiments to determine the value of the spices as antiseptics were made, using water infusions, acetic-acid extracts, and oil extracts.

WATER INFUSIONS

In making the water infusions 20 grams of the whole spices, with 200 cc of water, were boiled for forty-five minutes. This is approximately the length of time that the spices are cooked in the ketchup in the factory. The liquid was then filtered and from 0.1 to 5 cc of the filtrate was used in 10 cc of tomato bouillon. The same organisms were used as in the former experiments.

The tests showed that cinnamon and cloves were the strongest antiseptically. These checked growth when used in small amounts, but it required 3 cc of the cinnamon and 1 cc of the cloves to inhibit the growth of the mold. Mustard, paprika, and cayenne pepper checked growth also, but 5 cc, the highest strength used, did not inhibit growth. The ginger, mace, and black pepper had no apparent effect in the quantities used.

The effect of the spices on the development of the yeast was somewhat different from their effect on Penicillium. The cinnamon showed the strongest action, 3 cc being effective, whereas 5 cc of the cloves was required. The cayenne pepper came next in effectiveness, and after that the black pepper. The ginger, mace, and mustard solutions had no effect in the strengths used.

The remainder of the spice infusions were kept in glass-stoppered bottles in the laboratory, and in a few weeks’ time there was a coating of mold formed over the surface of the mace, the mustard, and the black and cayenne peppers. The paprika had small, stunted colonies dotting the surface.

At the time that these experiments were made a quantity of the ground spices were placed in large petri dishes and water was added to make a heavy paste. One set of these was inoculated with the mold, and another set with the yeast, and all were kept in a warm place. No development of either organism appeared on the cinnamon, cloves, or mustard; on the others a growth first showed in three days. On a normal medium growth appears in twenty-four hours. On the mace, paprika, and cayenne pepper the Penicillium and yeast with which the pastes were inoculated were overgrown in a few days with black mold (Rhizopus nigricans).

ACETIC-ACID EXTRACTS

In the manufacture of ketchup acetic-acid extracts of the spices are sometimes used instead of the whole spices, on account of their supposed antiseptic properties as well as their greater strength and convenience in handling. One minim of the standard acetic-acid extracts is equal in strength to 1 grain of the whole spices. The acid extracts obtained included allspice, celery, cloves, coriander, garlic, and black pepper.

In the tests 0.1, 0.2, 0.3, 0.4, 0.5, and 1 cc, respectively, of the extract was added to 10 cc of tomato bouillon. One set was inoculated with the mold and another set with the yeast. In the case of the mold, no growth occurred with the allspice and cloves; the celery checked the growth materially, there being no indication of mold until the sixth day. Normally a fairly strong growth occurs in twenty-four hours. In the solution containing 0.3 cc there was only one small colony in thirteen days, and no further development. In the solution containing the coriander, the growth in the 0.5 cc solution did not appear for three days, the 1 cc solution showing no growth. The garlic had practically the same effect as the coriander, while the black pepper was stronger, no growth appearing in the solution containing 0.5 cc.

The yeast was slightly stronger in resisting the effect of the extracts. No growth appeared with the allspice and cloves; 0.5 cc of the celery and 1 cc of the coriander were required to inhibit growth, and the garlic and black pepper gave similar results, a weak development occurring in the solutions containing 1 cc.

OIL EXTRACTS

Oil extracts of the spices were tested in the same manner as the water infusions and the acetic-acid extracts. The oils were so strong that in order to handle them easily they were mixed with equal volumes of alcohol, except that the mace, which was in the form of a paste, was mixed with two-thirds its volume of alcohol. To 10 cc of tomato bouillon were added 0.1, 0.2, 0.3, 0.4, and 0.5 cc, respectively, of the oils of cinnamon, cloves, mace, mustard, and black pepper.

In the case of the mold, there was no development in the solutions containing cinnamon, cloves, and mustard; in those containing mace and black pepper the development was slower than the normal, that in the black pepper being more pronounced. On the yeast the effect was similar, no development occurring in the cinnamon, cloves, and mustard, and a retarded development taking place in the mace and black pepper, that in the black pepper being the more pronounced.

The experiments show that some of the spices, notably allspice, cinnamon, and cloves have decided antiseptic value, but that the peppers are not as valuable as is generally supposed.

The oil extracts have been advocated for use in ketchup instead of the whole spices, but in quantities which would be useful antiseptically their use would be objectionable, for when present in approximately the same proportions as are the whole-spice infusions, the flavor is too strong and masks the more delicate flavor of the tomato. The acetic-acid extracts are more effective than are the water infusions, and they are not objectionable in the ketchup.

VINEGAR AND ACETIC ACID

An experiment was made to determine the antiseptic value of vinegar and acetic acid. Commercial 50-grain distilled vinegar was used. It was found that when 30 per cent of this vinegar was added to the tomato bouillon the development of mold was checked and the extent to which it was checked increased with the increased amounts of vinegar. The development in the solution containing 30 per cent of the vinegar was two days later than the normal in starting, while the solution containing 100 per cent was eleven days delayed and showed but little growth.

An 80 per cent solution of glacial acetic acid was used. One-half of 1 per cent added to the tomato bouillon checked growth to the same extent as 30 per cent of vinegar, and no development occurred when the quantity was increased to 2 per cent.

Experiments were then made in which vinegar was added to the ketchup in proportions varying from 1 part in 32 to 1 part in 8, with the result of greatly delaying the appearance of the mold as the proportion increased. With the increase in vinegar it was necessary to add sugar and slightly more spices to overcome the pungency of the acid and thus insure good flavor. The addition of the vinegar to the pulp had the effect of arresting the action of the oxidase and thus the bright color was maintained.

The usual custom in factory practice is to add the vinegar near the close of the cooking process otherwise a considerable portion of the acid will be driven off. This practice was followed in the experimental work, but it has since been found that continued heating in the presence of the acid has some effect upon sterilization, and therefore the increased amount of vinegar is effective not only because of the additional acid present, but also because the heating in the after process is thereby rendered more efficacious.

This line of experiments gives promise of practical results in producing a ketchup which will not only keep while in the bottle, but will also keep longer after it is opened. Each manufacturer must work out the quantities that could be used with his formula and still retain the character of his goods.

OIL

In ketchup manufacturing it is customary, if an agitator is not used, to put a small amount of fat in the kettle to check the ebullition during the reduction of the pulp. The amount used in this manner is not sufficient, however, to be apparent in the ketchup. Brannt4 states that in some factories, where the trimmings are allowed to accumulate for the season, they are given liberal doses of oils and condiments when cooked, in order to disguise their defects, so that the product can be placed on the market as “fresh tomato catchup.” That the use of oils is increasing is evident from the comparison of the ketchup of the past season with that of former years.

When oil is used in ketchup, it is easily detected under the microscope, as it appears in the form of shining, yellow globules which blacken gradually when treated with osmic acid. Besides this, the oil comes to the surface of the ketchup, where it can be seen readily, and if considerable oil has been used a distinct layer is formed. When the ketchup has been made for some time, the oil changes so that the ketchup has a peculiar “greasy” odor, or the oil may be so changed as to give a decidedly rancid smell to the ketchup. Oil usually causes a deterioration in flavor and odor, though some of the ketchups to which it has been added do not spoil readily. Olive oil, cottonseed oil, and oleomargarine are used. That the oil is not considered one of the regular known ingredients of the ketchup is shown by the failure to declare its presence on the label.