Полная версия

The ABC of Qualimetry. The Toolkit for Measuring Immeasurable

There are two principal fallacies here. One is that the magnitude of increase in the value of the quality index was determined incorrectly, taking no account of the fact that an improvement in the value of a property of an object byα%almost always leads to an improvement in its quality index by β% (with α<β).

The second fallacy is neglect the following: a quality improvement in one property of an object will result in an improved quality index of the object to the extent that none of its other property indices has deteriorated. Yet, this is a fairly common occurrence. Let us suppose that in the above case a 30%increase in the life of a component part is often accompanied by an increase in its mass. This leads to a deterioration of its “product mass” property by so many percent. Unless we make a qualimetric calculation we cannot say a prioriwhether – and by how many per cent – the quality of the product deteriorated or improved. (Proofs of both these assertions are to be found in books on theoretical qualimetry; see, e.g., [2]).

Therefore, it often happens in practice that the termquality control is applied to processes which, in control theoretic terms, cannot be considered quality control and, not infrequently, cannot be even called quality improvement because in reality they only ensure some indefinite quality variation (see lines 2 and 5 in Table 1 above).

The grey background in Table 1 is used to highlight two lines, 10 and 11, which represent the criteria to be met if we are to have a real quality control process. Line 10 describes the conditions under which, as common sense tells us, quality control is really achievable. That is to say, it is about a quality improvement is achievable to a pre-set extent within a pre-set time.

The case introduced by line 11 also belongs to control processes, though it is less apparent in the usual sense. Its only difference from case 10 is that the latter achieves a quality improvement (accordingly, ΔKK> 0), whereas in case11 no improvement is envisioned, the only intention being to keep quality from deteriorating within a pre-set time period, i.e., to set it at a constant level, ΔKK= 0).

The process described in line 12 is also related to quality control is totally unobvious to common sense. In pure theory, however, one can imagine a situation where the goal is not to increase but to decrease the quality of a product within pre-set limits and within a pre-set time, e.g., in order to cut production costs so as to boost demand. Since this is more academic than a real-life situation the respective line (12) in Table 1 was not highlighted with grey.

The foregoing interpretation of quality and quality control suggests that if we are to control quality we must be able to calculate the values of ΔKK. To do it we must, in turn, be able to quantify or estimate quality using its index KK. Consequently, we need a tool for the quantification of quality, which is provided by qualimetry.

There were also other factors, which made the appearance of qualimetry necessary, even inevitable. They will be discussed in the section that follows.

1.1.3. The Origin, Growth and Future of Qualimetry

1.1.3.1. The Reasons Behind the Rise of Qualimetry as a Science

Qualimetry is a consequence of knowledge quantification

The term qualimetry (from the Latinquale, “of what kind”, and the Greek μετρεω, “to measure”) was initially applied to a scientific discipline studying the methodology and problems of quantitative assessment of the quality of various objects, mainly of industrial products [3]. By 1970 enough experience had accumulated to permit a thorough investigation of qualimetry, its subject matter and its relations with various scientific fields. At the same time there was a growing awareness of the need to expand the scope of qualimetry from product quality (which was the focus of some researchers) to the quality of objects of whatever nature, including socio-economic objects such as the quality of life.

When the term (and the respective concept) was first used it seemed unexpected, almost fortuitous; some still regard it so.

However, it would be wrong to speak of the fortuity of qualimetry. On the contrary, its appearance should be seen as one of the many perfectly natural signs of the general broadening of the scope of quantification and the use of quantitative methods in scientific and, generally, cognitive activities at large.

The universal and imperative nature of this tendency to expand the use of quantification as a major tool of cognition was succinctly stated by Galileo, who said “Measure what is measurable, and make measurable what is not so.” The Russian Mathematician D. B. Yudin expressed nowadays essentially the same idea: “Quality is a yet unknown quantity”.

Many great minds were aware of the important influence that mathematics, as a general framework of quantification techniques, has exerted on the development of science.

K. Marx was of the opinion that a subject could be called a science if it had a mathematical foundation. A century before him, I. Kant wrote in hisMetaphysical Foundations of Natural Science, “I maintain, however, that in every special doctrine of nature only so much science proper can be found as there is mathematics in it”. Three centuries before Kant, Leonardo made a similar statement: “No human investigation can be called real science if it cannot be demonstrated mathematically”. Five centuries before Leonardo, in the 9th century, the famous Arab scientist Abu Yusuf Ya’qub ibn Ishaq al-Kindi, who saw in mathematics the basis and prerequisite of all science, including philosophy and natural history, pursued a similar line of thought. Another thirteen centuries earlier the Greek philosopher Xenocrates of Chalcedon expressed the ancients” idea of mathematics in the following maxim: “Mathematics is the handle of philosophy”. Dozens of years before Xenocrates, or 2300 years before our time, his teacher Plato said, “Exclude from any science mathematics, measure and weight, and it is left with very little”.

Quantification is steadily broadening its scope of application, as evidenced by the growth of scientific disciplines or technical problem solving techniques that include the Greekμετρεωin their name. Here are a few examples:

Absorptiometry; autometry; autorefractometry; adaptometry; axiometry; actinometry; algometry; amperometry; angiostereometry; anthropometry; astrocalorimetry; astrometry; astrophotometry; audiometry; acidimetry; batimetry; biometry; bibliometry; veloergometry; visometry; viscosimetry; gigrometry; hygrometry; hydrometry; glucometry; gravimetry; gradiometry; densitometry; didactometry; dilatometry; dynamometry; dielectrometry; dosimetry; dopleometry; isometrym impedancemetry; inclinometry; interferometry; cliometrics; calipometry; calorimetry; chelatometry; conductometry; craniometry; coulometry; lipometry; luxmetry; mediometry; mercurimetry; morphometry; scientometrics; nitritometry; optometry; ordometry; oscillometry; optometry; perimetry; pirometry; pH-metry; planimetry; polarimetry; psychometrics; potentiometry; pulseoxymetry; radiometry; radiothermometry; redoxmetry; roentgenometry; refractometry; sensitometry; sociometry; spectrometry; spectroradiometry; spectropolariometry; spectrophotometry; spirometry; spiroergometry; stabilometry; stereometry; sphincterometry; tacheometry; tensometry; technometry; tonometry; turbidemetry; uroflowmetry; fluorimetry; photogrammetry; photocolorimetry; photometry; chronometry; equilibriometry; econometrics; exponometry; electrometry; echobiometry. Qualimetry is also a member of this steadily expanding family. (It would be wrong, however, to believe that every discipline using quantification hasmetry / metrics in its name.)

Qualimetry: A Tool for Enhancing the Efficiency of Any Kind of Work

What happened for the qualimetry to appear in the 1960s?

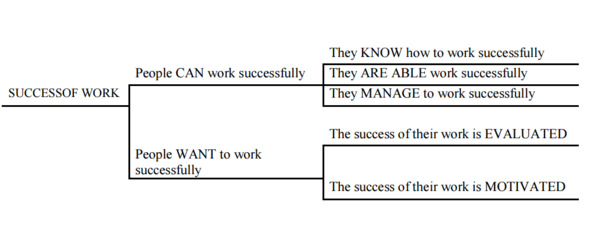

Modern management science has formulated five necessary and sufficient conditions for the success of any work, which can be represented by a “condition tree” (Figure 1).

Figure 1. Necessary and sufficient conditions for the success of any work

Four of these conditions, TO KNOW, TO BE ABLE, TO MANAGE, and TO MOTIVATE, are relatively easy to meet technically; regulatory documents for respective calculations are already in place. For example, every productive industry uses its own rate setter’s handbook (or a similar document), which is used to calculate the workforce and the time and tools needed to perform a piece of work (TO MANAGE condition). Other documents, like wage rate books, specify the requirements to be met in selecting the workforce to do some work successfully (TO BE ABLE condition).It is relatively easy to secure the TO KNOW condition: you only need to set the work executors a task. Finally, to meet the TO MOTIVATE condition all businesspersons or managers have a broad range of stimulatory actions they can use on their subordinates: material or moral; positive (“carrot”) or negative (“stick”); individualized or team-directed; one-off or time-phased, etc.

The TO EVALUATE condition is a very different case. What we evaluate is work. Any work (and its output) is characterized by three parameters: quantity, cost and quality. Arguably, the numerical evaluation of the quantity and cost parameters does not present any essential difficulties to most occupations in the real sector.

We have a different situation with the quality parameter. Here two aspects must be taken into account: the quality of individual labour and the quality of teamwork. As for individual labour, evaluating is just a trivial task (particularly if it is to be done in a quantitative form and with due regard for the many characteristics that constitute its quality).

Evaluating even the simple labour of an industrial worker poses difficulties: it is by no means always that it can be evaluated using a simple reject rate index. These difficulties multiply when it is a matter of quantitative assessment of the quality of complex labour, e.g., brainwork.

Here is an example to illustrate the importance and complexity of this task. Back in the early 1970s a group of UNESCO experts surveyed 1200 research teams in Austria, Belgium, Finland, Hungary and Sweden. Their conclusion: the most vexed problem in raising working efficiency in science is the lack of a reliable methodology for assessing the quality of work of individual researchers and research teams. (Similar examples can be cited with respect of managers, health professionals, engineers, teachers, administrators, and some others.).

Let us now look at the issue of assessment of the quality of teamwork. It stands to reason that the quality of output is its most important characteristic. As already mentioned, the outcome of any teamwork is, a product, a service, some information or energy. Of these four the product is by far the most complex in terms of the quality assessment method and the most important in terms of the breadth of its existence domain, given that more than twenty million kinds of products are manufactured by developed economies over the world.

It all goes to show that:

1. In the present-day context, successful, i.e. effective, productive work is a key condition of the economic health of both an individual company and a country at large.

2. When we address the problem of increasing the success/efficiency of any labour the key element is the quantitative assessment— both of the process and the outcome of labour; primarily its product.

3. Of the three characteristics of labour (and its outcome) – quantity, quality and cost – quality is the most complex one in terms of quantitative assessment.

4. Until quite recently, the approach to the problem of quantitative assessment of quality (primarily of products) lacked sound methodological support. At best, isolated quality quantification techniques were created, which had not any sound and unified rationale to support them. As a result, different quantifications of the quality of the same object could be worlds apart if calculated by different methods.

5. A natural corollary to propositions 1—4: in the early post-WWII years every industrialised country felt the need for scientific rationalisation of methods of quantitative assessment of the quality of production work and its outcomes.

6. It was F. Engels who noted that when a technical need appears in society, it pushes science forward faster than a dozen universities. The origins of qualimetry can be seen as a natural response to a pressing need for generalisation and perfection of the techniques of quantitative assessment of quality.

1.1.3.2. History of Qualimetry: From Aristotle to Our Times

Theoretical Reason for the Relatively Late Origin of Qualimetry

One may ask: why did qualimetry appear as an independent scientific discipline in the 1960s and not before?

There were two principal reasons.

The first, which we will tentatively call “theoretical”, is as follows. The termquality has existed in science for as much as 2500 years, since the days of Aristotle. His usage of the term referred to different concepts. (For convenience, hereafter the respective definitions for these concepts will be given a modern interpretation, in a concise form, which are more familiar and comprehensible than Aristotle’s definitions. – Auth.). Subsequently, it was depending on its interpretation that it was decided whether or not it was necessary and possible to quantify/estimate this concept.

Interpretation I: Quality is an essential certainty of an object (i.e., a thing, phenomenon or process), whichmakes it what it is and not something else. In other words, quality is the kind of certainty that distinguishes, say, a human from a horse or a table.

Конец ознакомительного фрагмента.

Текст предоставлен ООО «Литрес».

Прочитайте эту книгу целиком, купив полную легальную версию на Литрес.

Безопасно оплатить книгу можно банковской картой Visa, MasterCard, Maestro, со счета мобильного телефона, с платежного терминала, в салоне МТС или Связной, через PayPal, WebMoney, Яндекс.Деньги, QIWI Кошелек, бонусными картами или другим удобным Вам способом.

Примечания

1

Some times information and energy are subsumed under products or services.

2

Distribution may be subsumed under consumption.

3

For simplicity here in after they will all be referred to asmanagers.

4

For the same reason we will exclude from consideration other, less common types of qualimetric techniques.